Many overseas customers keep asking us the same question, whether in emails or during video calls: Is your busbar machine shipment reliable? Do you just assemble them carelessly on a production line and ship them out without real inspection?

Today, we show you the truth with no empty words and no fancy scenes. We take you into our production workshop to show you how a qualified CNC busbar processing machine is made step by step – from raw materials coming into the factory to final busbar machine shipment. We want you to see every process clearly and buy with complete confidence

We are an original manufacturer with 22 years of experience. We are not a middleman, nor a small workshop that chases quick money with low prices. What has made us stand firm in the industry for 22 years is just two words: being honest.

Making equipment is like being a good person – it needs conscience. We never cut corners, and we never do meaningless flashy promotion. For us, whether a busbar machine shipment is good or not is not decided by us, but by our customers. Only when the machine runs without failures and keeps stable efficiency after one or two years of use, can it be called a good busbar machine shipment.

Therefore, no matter how big or small the order is, every busbar machine shipment leaving our factory must go through these 5 inspection steps seriously, and none can be skipped:

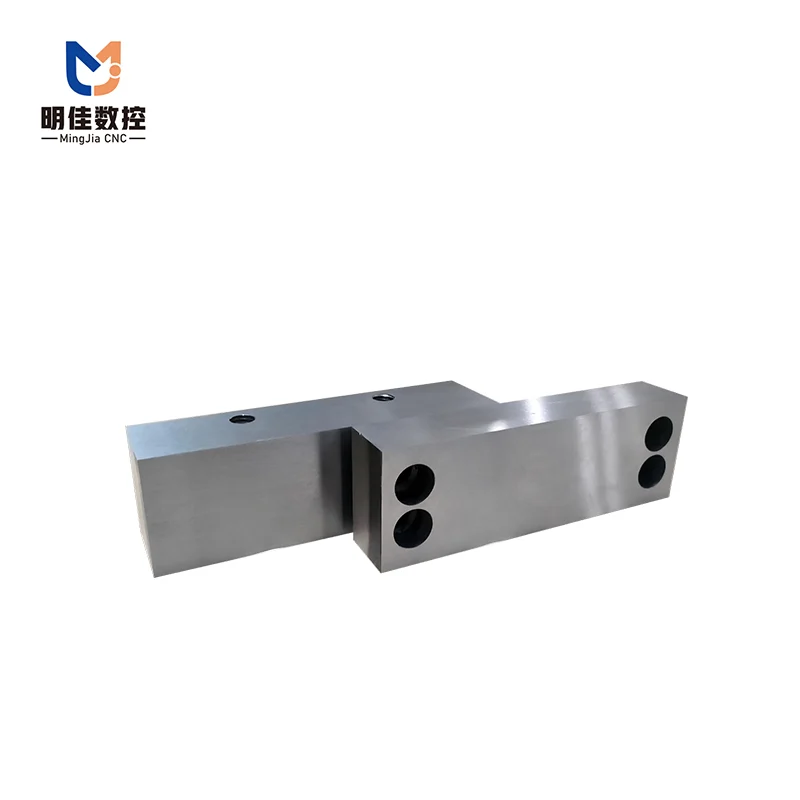

1.Raw Material Inspection for Every Busbar Machine Shipment

This is the first gate of quality, and we never make it careless. Every batch of steel plates and every set of quenched alloy cutters is sampled and inspected when they arrive. Any material that fails to reach the standard in quality or hardness will be returned directly, no matter how cheap it is. We never use inferior materials. We would rather spend more on costs to control quality from the source, avoiding machine breakdowns and delays to customers’ production. For example, a client from Malaysia once told us that our busbar machine shipment saved them from frequent maintenance issues they had with cheaper alternatives.

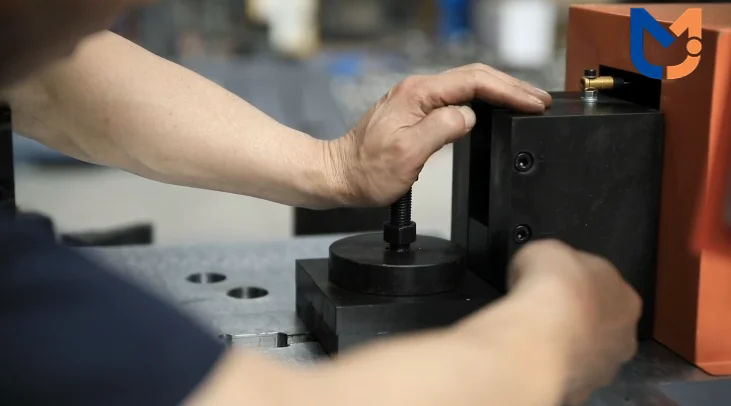

2.Component Assembly for Every Busbar Machine Shipment

The core CNC system is never assembled casually by new workers. It is all hand-assembled by our senior engineers with more than ten years of experience. These skilled workers handle every detail perfectly. Every wire and every connector is installed tightly and accurately. After assembly, they check the circuits and connections manually to ensure zero errors. After all, the CNC system is the “brain” of the machine – if the brain goes wrong, the whole busbar machine shipment is wasted.

3.Dry Run Testing for Every Busbar Machine Shipment

After the machine is fully assembled, we do not move to the next step right away. We let it run continuously for 2 hours. During these 2 hours, our workers stay beside the machine, testing the three core functions of punching, shearing and bending repeatedly. They try different parameters and operations to make sure the machine runs stably, with no noise, no jamming, and every function works well without any small faults before busbar machine shipment.

5.Accuracy Calibration for Every Busbar Machine Shipment

We think more carefully about this than our customers. After all, the machine has to travel across the ocean, with long-distance sea transportation and multiple loadings and unloadings, which can easily lead to bumping and damage during busbar machine shipment. So every machine is fully treated with anti-rust protection first, then wrapped with thick foam cushions, and finally packed into reinforced solid wooden crates. We also stick clear moisture-proof and fragile labels on the outside. We pack them securely to avoid scratches and damages during busbar machine shipment as much as possible, ensuring the machine arrives at your place in the same perfect condition as when it left the factory.我们对此的思考比客户更为谨慎。毕竟,机器需要跨洋运输,进行长距离海运和多次装卸,运输过程中容易碰撞和损坏。因此,每台机器都先经过防锈处理,然后用厚泡沫垫包裹,最后装进加固的实木箱子里。我们还会在外面贴上透明、防潮且易碎的标签。我们会妥善包装,尽量避免母线机器运输过程中出现划痕和损坏,确保机器以出厂时的完美状态抵达您家。

Some people may ask: Will such strict quality inspection delay the busbar machine shipment? To be honest, we would rather spend an extra 1–2 days checking every machine’s quality thoroughly than send you a problematic machine. After-sales service overseas is much more complicated than domestic service. Problems not only waste time but also affect your production schedule. We cannot afford to lose our reputation, nor can we let down our customers’ trust in our busbar machine shipment.

Making equipment is about conscience; doing foreign trade is about trust. For 22 years, we have been making equipment steadily and checking quality strictly for every busbar machine shipment. We do not pursue the fastest delivery, only the most stable quality; we do not pursue the lowest price, only the most durable machines.

If you still feel worried, you can have a video call with us at any time. We will show you our real-time workshop production and our workers doing quality inspection before busbar machine shipment. We have nothing to hide. The real look of our factory and the reliable quality of our busbar machine shipment are our greatest confidence.

For more details on our product line, you can check out our https://mingjiacnc.com/ You can also learn more about international standards for electrical equipment at the IEC official website https://www.iec.ch

In the future, we will always keep these standards, make every machine with care, and provide stable, reliable and trustworthy busbar machine shipment for customers all over the world.