Devoted to the development of CNC busbar machine and CNC sheet metal equipment

The main CNC busbar machine of the company are CNC busbar processing machine, CNC busbar punching and shearing machine, CNC busbar bending machine, busbar processing machine, turret busbar processing machine, economic busbar processing machine, busbar leveling machine and other busbar processing equipment and transformer winding machine, moored winding machine, transformer corrugated sheet forming machine, circular shearing machine and other transformer processing equipment.

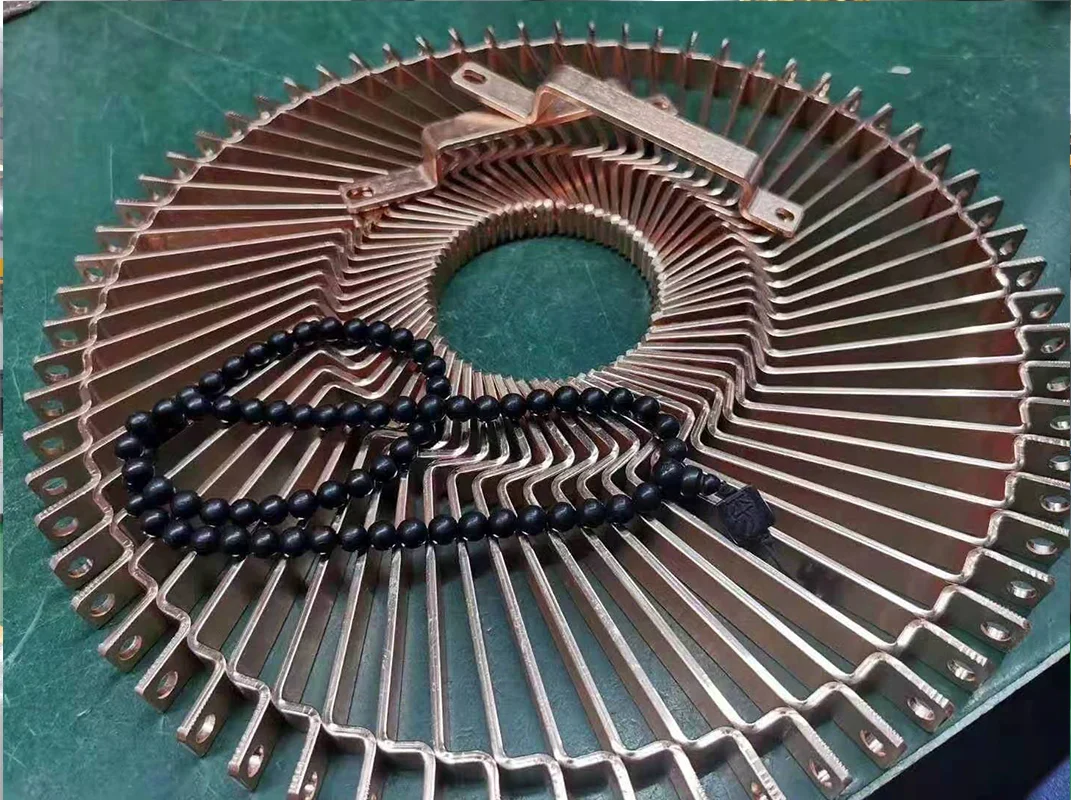

Our Busbar Machine Series

It is widely used in industries such as high and low voltage switch cabinets, transformers, electrical switches, and communication equipment.

After evaluating multiple busbar processing machine suppliers, we ultimately selected this equipment. It delivers consistently precise performance in punching, shearing, and bending, with the processed copper busbars exhibiting excellent dimensional consistency that fully meets our distribution cabinet assembly requirements. The intuitive interface requires minimal training, and the after-sales team responds promptly, resulting in a highly satisfactory overall user experience.

This busbar processing machine has significantly improved our production efficiency. Processes that previously required multiple machines can now be completed by a single unit. The equipment features a robust structure and operates smoothly, maintaining stability even during prolonged continuous operation. The technical support team provided professional guidance during the installation and debugging phases.

As a first-time purchaser of a busbar processing machine, we received extensive professional guidance during the initial selection phase. The equipment demonstrated stable operation after installation, with straightforward operation requiring only minimal training for operators. Both processing efficiency and precision surpassed our expectations.

With decades of expertise in power equipment manufacturing, we place stringent demands on the stability of busbar processing equipment. The new equipment delivers significant improvements in both processing precision and efficiency, while offering user-friendly maintenance and professional after-sales support – making it an ideal partner for long-term collaboration.

Busbar Machine Advantages

4 items | Busbar Machining Machine

The busbar machining machine utilizes CNC technology and a precision-engineered, high-rigidity monocoque frame structure with a stable hydraulic system, enabling efficient and accurate execution of processes such as punching, shearing, and bending. The finished busbars feature precisely positioned holes, smooth cuts, and consistent bending angles, effectively minimizing assembly errors. This meets the stringent precision requirements of distribution cabinets and switchgear, thereby ensuring reliable busbar connections.

A single device integrates multiple processing functions, reducing the transfer of workpieces between different equipment and manual handling. Compared to traditional single-process equipment, the overall processing efficiency can be improved by approximately 50%–80%, making it particularly suitable for medium-to-large power distribution plants and electrical equipment manufacturing enterprises for long-term stable production.

With exceptional adaptability, it processes copper and aluminum busbars of various specifications and materials, meeting diverse production needs for high-and low-voltage electrical equipment. Customization is supported based on customers' standard dimensions, processing capacity, voltage requirements, and automation needs, ensuring optimal performance alignment with actual production demands.

The system features user-friendly operation and safety protection devices, significantly reducing manual operation difficulty and eliminating occupational injury risks. Key hydraulic and electrical components are selected from mature and reliable brands, ensuring stable and durable equipment with convenient maintenance, thereby lowering long-term operational costs.

FAQ

8 items | Comprehensive Edition

The equipment is primarily designed for manufacturing copper and aluminum busbars, particularly suitable for standard rectangular busbars. The processing width, thickness, and length can be configured or customized according to the client's specific requirements, ensuring long-term stable operation without overload.

The standard configuration typically includes punching, shearing, and bending stations, enabling continuous multi-step processing. This multi-station design effectively reduces the turnaround time of the busbar between different machines, thereby enhancing overall processing efficiency.

The equipment features a high-rigidity integral structure and a stable hydraulic system, combined with precise positioning technology to ensure consistent hole positions, lengths, and bending angles, making it ideal for batch continuous production.

The system supports customized configurations including tonnage capacity, busbar specifications, power voltage, control modes, mold configurations, and automation levels, ensuring seamless alignment with clients' actual production requirements.

The operational logic is clear, and the control system is user-friendly. Ordinary employees can operate independently after brief training, reducing reliance on highly skilled workers.

The equipment is engineered for industrial continuous operation. With proper operation and maintenance, it maintains stable performance under high-intensity conditions.

Routine maintenance primarily involves basic inspections and periodic upkeep, which are low-complexity. We provide detailed maintenance guidance to help extend the service life of your equipment.

We provide remote technical support, video tutorials, hands-on training, and spare parts assistance, covering basic operations, mold assembly/disassembly, routine maintenance, and troubleshooting (including alarm handling and hydraulic leak resolution) to ensure long-term stable operation of your equipment.