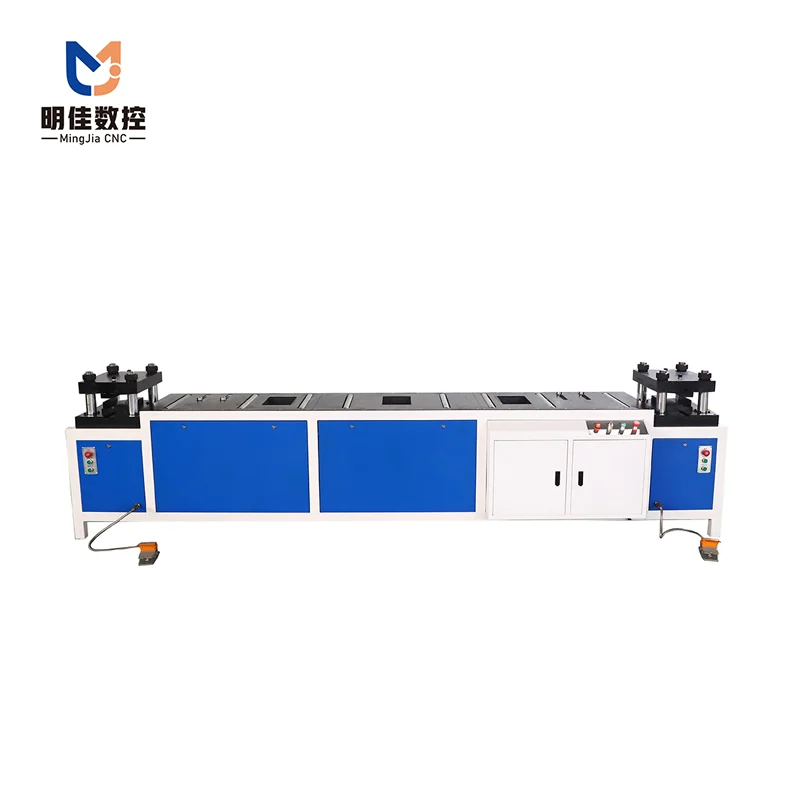

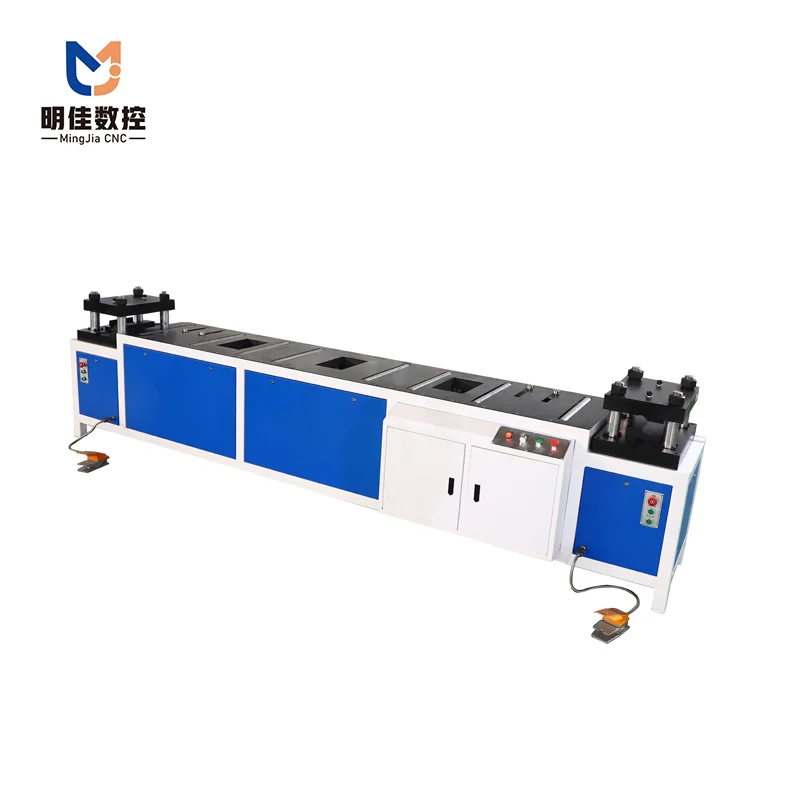

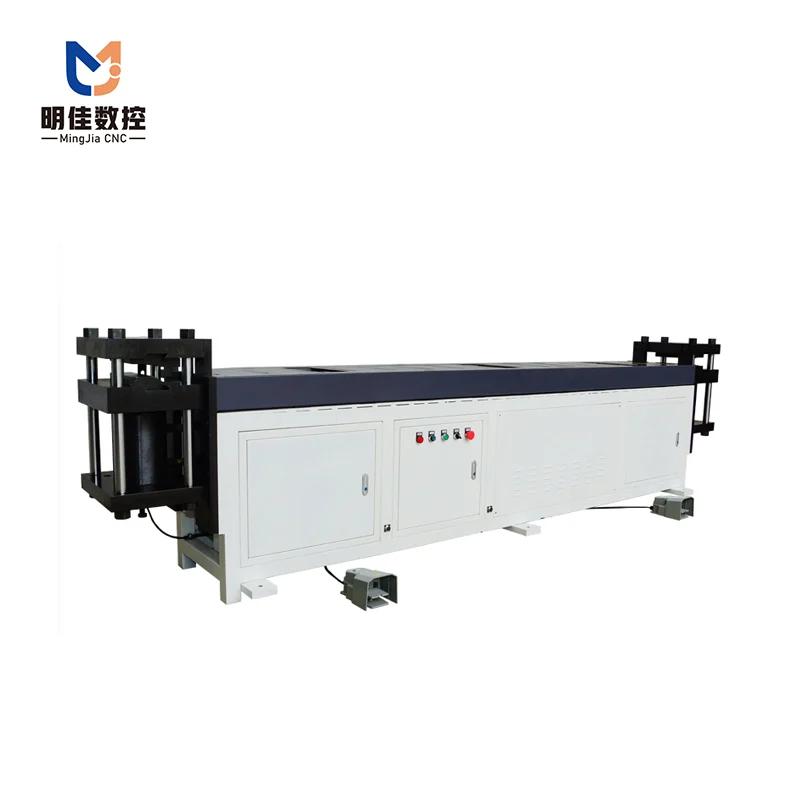

Dual-End Busbar Bending Machine

main features

1. Dual-End Busbar Bending Machine: High-Efficiency Dual-End Operation, Doubled Productivity

The dual bending units adopt a high-precision four-column linear slide rail and a dual-frame structure. The upper and lower beams are installed vertically and parallel, ensuring die flatness and higher bending accuracy. The two units operate independently, allowing simultaneous bending on both ends of a workpiece in one cycle without repositioning. This increases efficiency by over 30% compared to single-end machines, with a single bending cycle time of ≤10 seconds. It supports processing multiple pieces simultaneously and cyclic operation, significantly reducing process steps and manual labor, making it ideal for batch production.

2. Outstanding Precision and Stability

Dual-End Busbar Bending Machine is equipped with a dual-cylinder, upward-acting, stepless pressure-adjustable hydraulic system, coupled with high-tonnage oil cylinders and imported seals, ensuring stable and fluctuation-free pressure output. Bending accuracy can reach ±0.1mm, with repeat positioning accuracy ≤0.1mm.

3. Robust and Durable Construction

The overall welded frame is tempered for stress relief. Four guide columns support the bending units, secured by high-strength nuts to prevent deformation during long-term use. An adjustable wedge combined with a mechanical synchronization structure provides real-time compensation for clearance deviations.

4. User-Friendly Operation and Easy Maintenance

For mainstream models, regular operators can be trained to operate independently within one day. Supports multiple modes including jog, automatic, and continuous operation. Operating noise is ≤60 dB, complying with industrial hygiene standards.

Most dies of the Dual-End Busbar Bending Machine are single-piece formed, robust, durable, and easy to replace.

5. Comprehensive Safety and Strong Adaptability

Features safety functions such as emergency stop and stop-and-continue. Complete protective structures are in place to minimize operational risks.

6. Wide Material and Specification Compatibility

Suitable for busbar materials like copper and aluminum. The processing range covers specifications from 3×30mm to 6×260mm, meeting the needs of applications such as elevator control cabinets, chassis & cabinets, and busway systems.

technical parameter

| Item | Unit | Parameter |

| Max. Bending Force | kN | 500 |

| Max. Bending Width | mm | 300 |

| Max. Bending Thickness | mm | 8 |

| Work Table Size (L×W×H) | mm | 4000 × 600 × 1200 |

| Main Motor Power | kW | 5.5 |

| Machine Weight | kg | 1100 |

FAQ

The equipment is primarily designed for manufacturing copper and aluminum busbars, particularly suitable for standard rectangular busbars. The processing width, thickness, and length can be configured or customized according to the client's specific requirements, ensuring long-term stable operation without overload.

The standard configuration typically includes punching, shearing, and bending stations, enabling continuous multi-step processing. This multi-station design effectively reduces the turnaround time of the busbar between different machines, thereby enhancing overall processing efficiency.

The equipment features a high-rigidity integral structure and a stable hydraulic system, combined with precise positioning technology to ensure consistent hole positions, lengths, and bending angles, making it ideal for batch continuous production.

The system supports customized configurations including tonnage capacity, busbar specifications, power voltage, control modes, mold configurations, and automation levels, ensuring seamless alignment with clients' actual production requirements.

The operational logic is clear, and the control system is user-friendly. Ordinary employees can operate independently after brief training, reducing reliance on highly skilled workers.

The equipment is engineered for industrial continuous operation. With proper operation and maintenance, it maintains stable performance under high-intensity conditions.

Routine maintenance primarily involves basic inspections and periodic upkeep, which are low-complexity. We provide detailed maintenance guidance to help extend the service life of your equipment.

We provide remote technical support, video tutorials, hands-on training, and spare parts assistance, covering basic operations, mold assembly/disassembly, routine maintenance, and troubleshooting (including alarm handling and hydraulic leak resolution) to ensure long-term stable operation of your equipment.

You Might Also Like

Leave Message

*Note: Please be sure to fill in the information accurately, and keep the communication unblocked, we will get in touch with you as soon as possible.