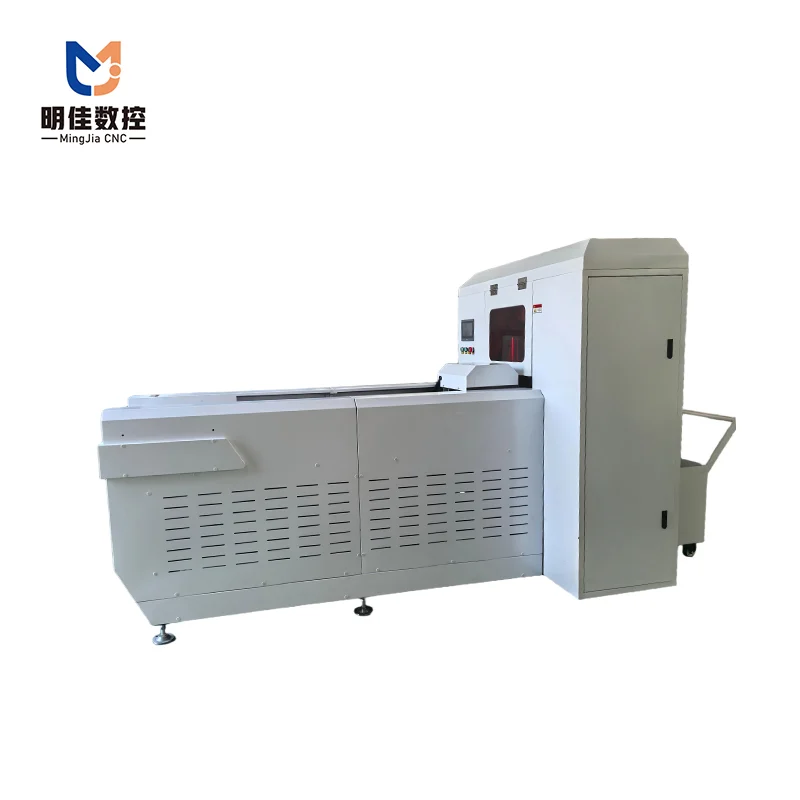

GJMX-L01 Busbar Connector Machining Center

main features

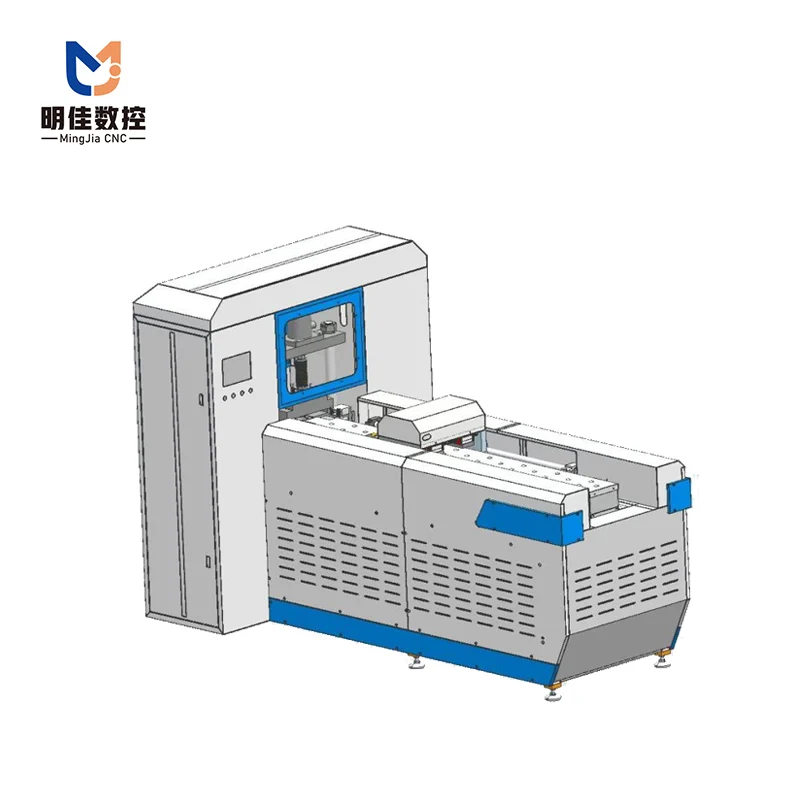

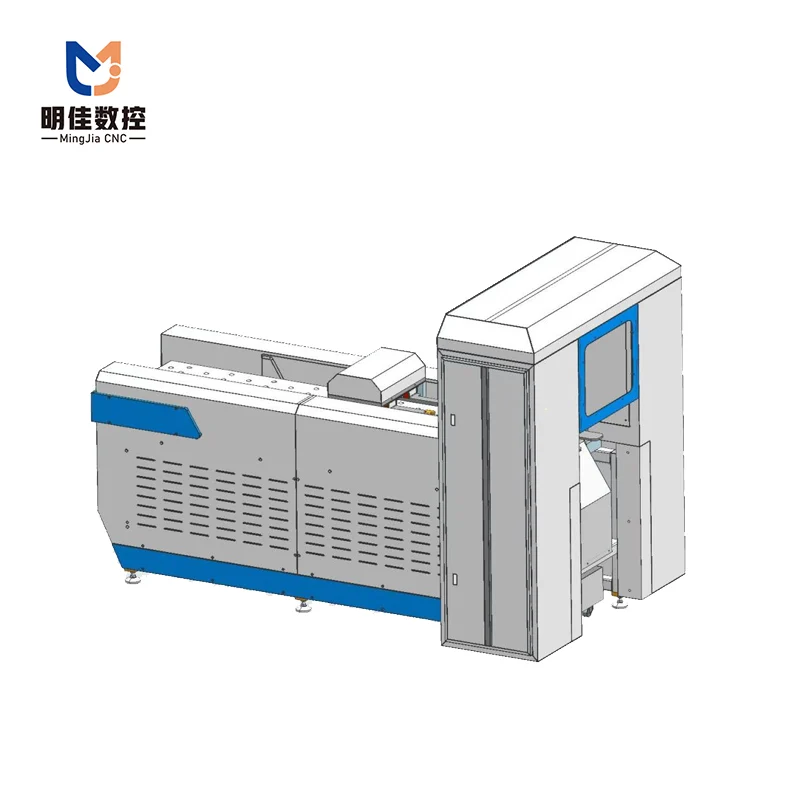

1.Dedicated & Efficient Processing: Designed specifically for busbar connectors. Features manual loading, automatic positioning, and dual-clamp auto-centering (front and rear of the tool station) to minimize material waste. Capable of automatic workpiece transfer, combining punching and forming operations in a single cycle for high efficiency and precision, producing uniform parts with minimal defects.

2.Intuitive Programming: Equipped with user-friendly, embedded programming software. The interface is simple to learn and operate, allowing for automatic continuous processing after inputting just a few key workpiece parameters, with real-time execution status display.

3.Precision Drive System: The X-axis (controlling workpiece length) is driven by a servo motor with CNC control, ensuring accurate length adjustment. Critical components utilize renowned domestic and international brands for enhanced reliability and longevity.

4.User-Friendly Operation: Features a Human-Machine Interface (HMI) for simple operation, real-time monitoring of program status and equipment alarms, and convenient parameter setting.

technical parameter

| Item | Unit | Parameter |

| Nominal Force | ||

| —Punching Unit | KN | 300 |

| —Shearing Unit | KN | 300 |

| —X-Axis Max. Speed | m/min | 48 |

| Stroke | ||

| —Punching Unit | mm | 20 |

| —Shearing Unit | mm | 20 |

| —X-Axis Travel | mm | 1180 |

| Operating Frequency | ||

| —Punching Unit | strokes/min | 65 |

| —Shearing Unit | strokes/min | 65 |

| —Hole Spacing Accuracy | mm/m | < ±0.2 |

| Sheet Processing Range | ||

| —Length | mm | 6000 / 3000 |

| —Width | mm | Customized (130, 115, 40, etc.) |

| —Thickness | mm | Customized (2.0, 2.5, 3.0, etc.) |

| Machine Footprint (L × W) | mm | 2500 × 1800 |

| Max. Hydraulic Pressure | MPa | 21.5 |

| Total Power | kW | 6 |

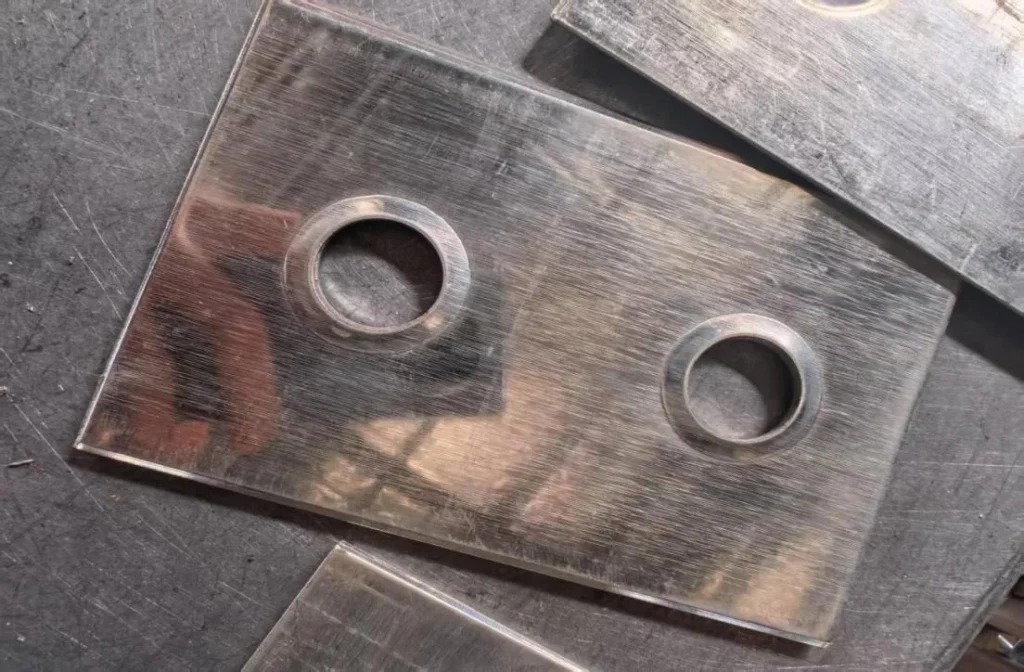

finished product display

FAQ

The equipment is primarily designed for manufacturing copper and aluminum busbars, particularly suitable for standard rectangular busbars. The processing width, thickness, and length can be configured or customized according to the client's specific requirements, ensuring long-term stable operation without overload.

The standard configuration typically includes punching, shearing, and bending stations, enabling continuous multi-step processing. This multi-station design effectively reduces the turnaround time of the busbar between different machines, thereby enhancing overall processing efficiency.

The equipment features a high-rigidity integral structure and a stable hydraulic system, combined with precise positioning technology to ensure consistent hole positions, lengths, and bending angles, making it ideal for batch continuous production.

The system supports customized configurations including tonnage capacity, busbar specifications, power voltage, control modes, mold configurations, and automation levels, ensuring seamless alignment with clients' actual production requirements.

The operational logic is clear, and the control system is user-friendly. Ordinary employees can operate independently after brief training, reducing reliance on highly skilled workers.

The equipment is engineered for industrial continuous operation. With proper operation and maintenance, it maintains stable performance under high-intensity conditions.

Routine maintenance primarily involves basic inspections and periodic upkeep, which are low-complexity. We provide detailed maintenance guidance to help extend the service life of your equipment.

We provide remote technical support, video tutorials, hands-on training, and spare parts assistance, covering basic operations, mold assembly/disassembly, routine maintenance, and troubleshooting (including alarm handling and hydraulic leak resolution) to ensure long-term stable operation of your equipment.

You Might Also Like

Leave Message

*Note: Please be sure to fill in the information accurately, and keep the communication unblocked, we will get in touch with you as soon as possible.