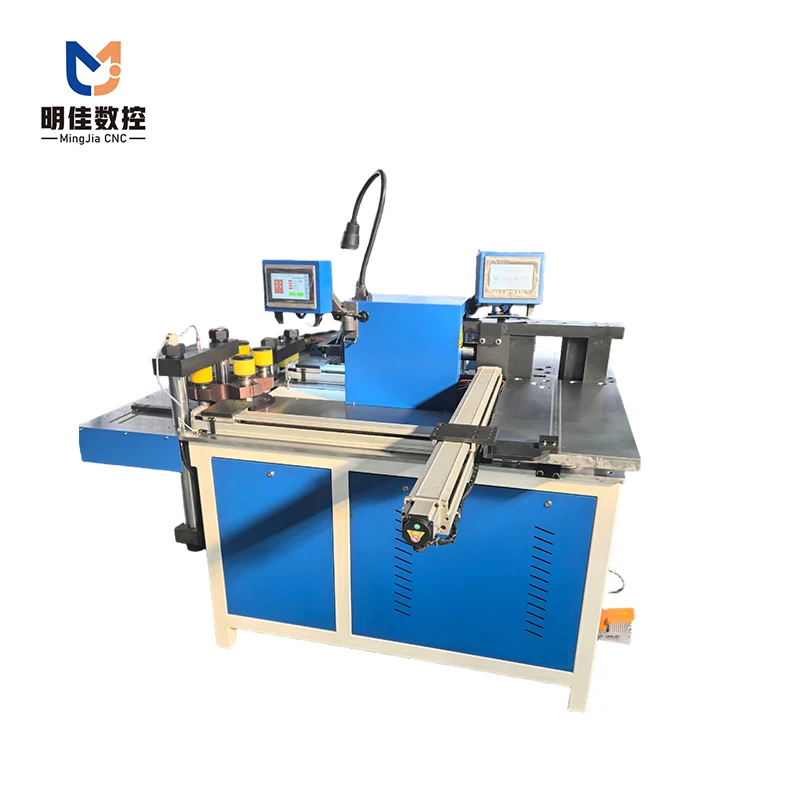

NCZMXB-303-3-S (Four-axis Servo) CNC Busbar Processing Machine

NCZMXB-303-3-S (Four-axis Servo) CNC Busbar Processing Machine is equipped with a German Siemens CNC system and servo motors, enabling automatic feeding and positioning for punching, shearing, and bending.

It features automatic calculations for bending angles, Z-bends, and material length, along with angle compensation, spring-back compensation pressure holding, and automatic start-stop functions.

Four Axis Servo CNC Busbar Processing Machine integrates three stations: punching, shearing, and bending, with the punching station employing a turret structure.

Designed for processing copper and aluminum busbars of various specifications, it ensures efficient operation. Users can perform diverse tasks including shearing, punching (round and oblong holes), flat bending, vertical bending, embossing, flattening, and twisting.

main features

All-in-One Precision: The Fully Automated Busbar Processing Center

Four Axis Servo CNC Busbar Processing Machine integrates punching, shearing, and bending into one seamless, automated workflow. Controlled by a PLC and servo motor system (replacing outdated relay control), it delivers unmatched stability, precision, and efficiency by eliminating manual marking and measurement entirely.

The system features automatic dimensional positioning, CNC angle calculation, Z-bending calculation, material length calculation, and automatic compensation for angle and inertia. It includes pressure maintenance and auto start-stop functions for consistent, high-quality results.

Three fully independent workstations (punching, shearing, bending) operate simultaneously, dramatically boosting overall productivity.

(Shearing Station): A dual-column structure with a precision shear edge produces clean, waste-free cuts—eliminating burrs and collapsed corners.

(Punching Station): Features a robust, customer-selectable 4/6/8 position rotary turret. Machined from a single integral workpiece, it guarantees absolute alignment between upper and lower dies, maximizing die concentricity and service life.

(Bending Station): Offers both open and enclosed configurations for maximum flexibility. Dual, truly independent workstations enable versatile bending operations.

Built for endurance, the hydraulic oil tank is constructed from 3mm-thick welded steel plates with phosphating treatment, ensuring long-term, stable performance without degradation.

technical parameter

| Nominal pressure | 300 kN for folding and punching, 400 kN for shearing |

| Maximum cutting dimension | 12×160mm |

| Cutting servo positioning accuracy | ±0.1mm |

| Servo positioning length | 0-1000mm (customizable per customer requirements) |

| Punching range | Φ4.3~25mm |

| Punching servo positioning accuracy | ±0.1mm |

| Punching servo positioning length | 0-1000mm (customizable per customer requirements) |

| Punching servo positioning width | 0-1000mm (customizable per customer requirements) |

| Maximum processing size for flat bend | 12×160mm |

| Maximum machining size for vertical bend | 8×80mm |

| Bending servo positioning accuracy | ±0.1mm |

| Bending servo positioning length | 0-1000mm (customizable per customer requirements) |

| Workbench dimensions | 1450mm × 1250mm |

| Dimensions of the machine | 2000mm × 1550mm × 1300mm |

| Machine weight | 1800g |

FAQ

The equipment is primarily designed for manufacturing copper and aluminum busbars, particularly suitable for standard rectangular busbars. The processing width, thickness, and length can be configured or customized according to the client's specific requirements, ensuring long-term stable operation without overload.

The standard configuration typically includes punching, shearing, and bending stations, enabling continuous multi-step processing. This multi-station design effectively reduces the turnaround time of the busbar between different machines, thereby enhancing overall processing efficiency.

The equipment features a high-rigidity integral structure and a stable hydraulic system, combined with precise positioning technology to ensure consistent hole positions, lengths, and bending angles, making it ideal for batch continuous production.

The system supports customized configurations including tonnage capacity, busbar specifications, power voltage, control modes, mold configurations, and automation levels, ensuring seamless alignment with clients' actual production requirements.

The operational logic is clear, and the control system is user-friendly. Ordinary employees can operate independently after brief training, reducing reliance on highly skilled workers.

The equipment is engineered for industrial continuous operation. With proper operation and maintenance, it maintains stable performance under high-intensity conditions.

Routine maintenance primarily involves basic inspections and periodic upkeep, which are low-complexity. We provide detailed maintenance guidance to help extend the service life of your equipment.

We provide remote technical support, video tutorials, hands-on training, and spare parts assistance, covering basic operations, mold assembly/disassembly, routine maintenance, and troubleshooting (including alarm handling and hydraulic leak resolution) to ensure long-term stable operation of your equipment.

You Might Also Like

Leave Message

*Note: Please be sure to fill in the information accurately, and keep the communication unblocked, we will get in touch with you as soon as possible.