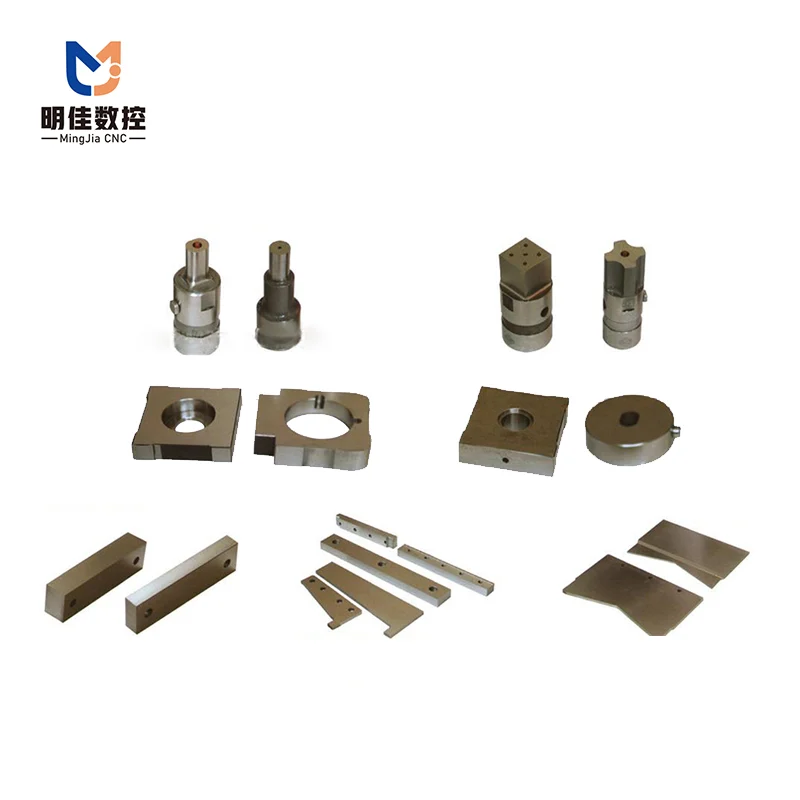

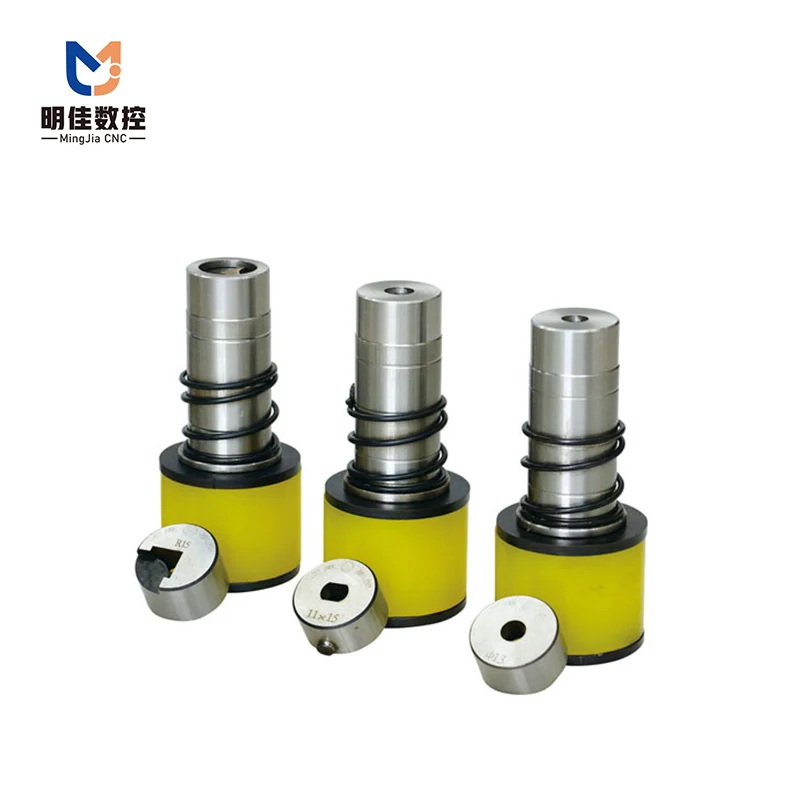

Punching Dies

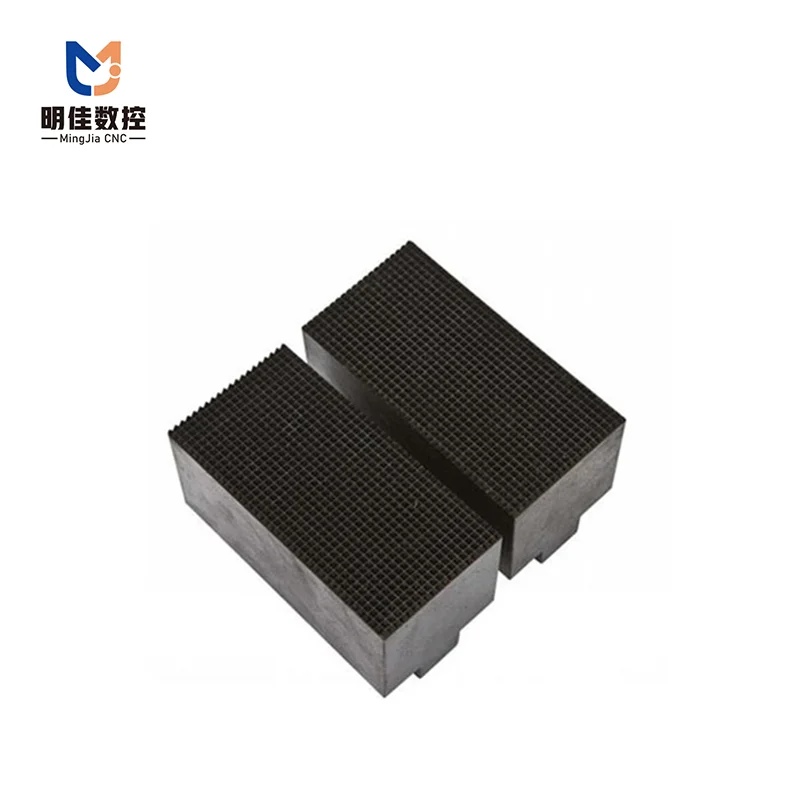

High Processing Accuracy

The mold is made of high-quality steel, featuring high precision and excellent wear resistance. It can ensure the consistency of the dimensions for the punching, shearing and bending of the busbar.

Long Service Life

The mold materials undergo heat treatment, resulting in high hardness and strong impact resistance. They can be used stably for a long time, reducing the frequency of replacement.

High Processing Efficiency

The mold structure is well-designed, enabling quick completion of punching, shearing, and bending processes, thereby improving the overall processing efficiency.

Safe and Reliable Operation

Precise die positioning effectively prevents processing errors and operational risks, enhancing overall operational safety.

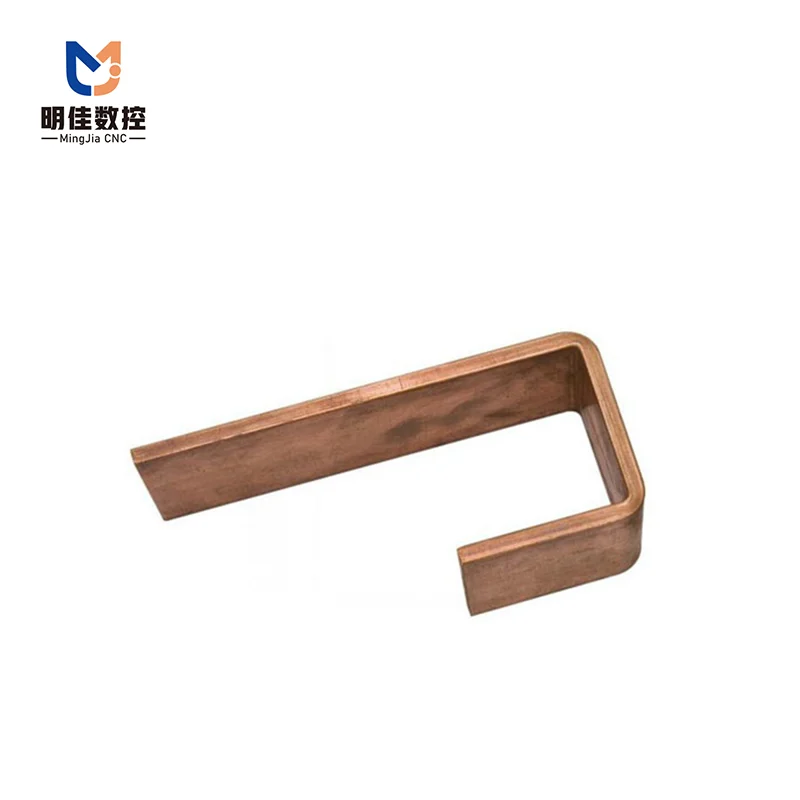

High Versatility

Molds can be replaced according to different specifications of copper or aluminum busbars to meet various processing needs, with a wide range of applications.

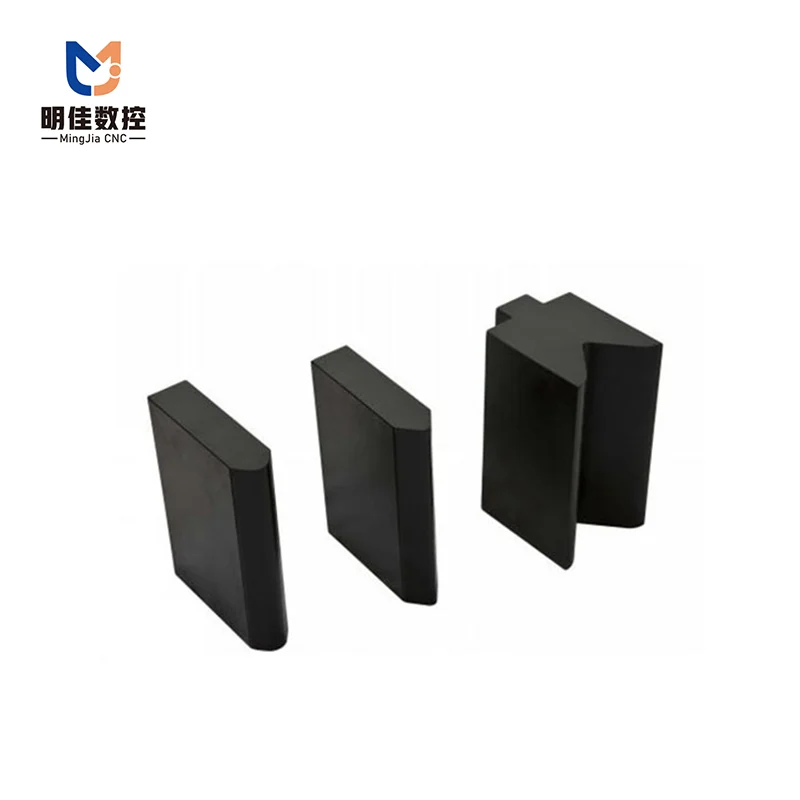

Superior Bending Precision

The bending die design is optimized, enabling various angles and shapes. This results in precise forming with minimal springback.

Easy Maintenance

The mold structure is simple, with convenient installation and disassembly, facilitating daily maintenance and upkeep.

Enhanced Product Quality

The mold processing is stable, significantly reducing defects such as burrs and deformations, and enhancing the overall quality of the busbar products.

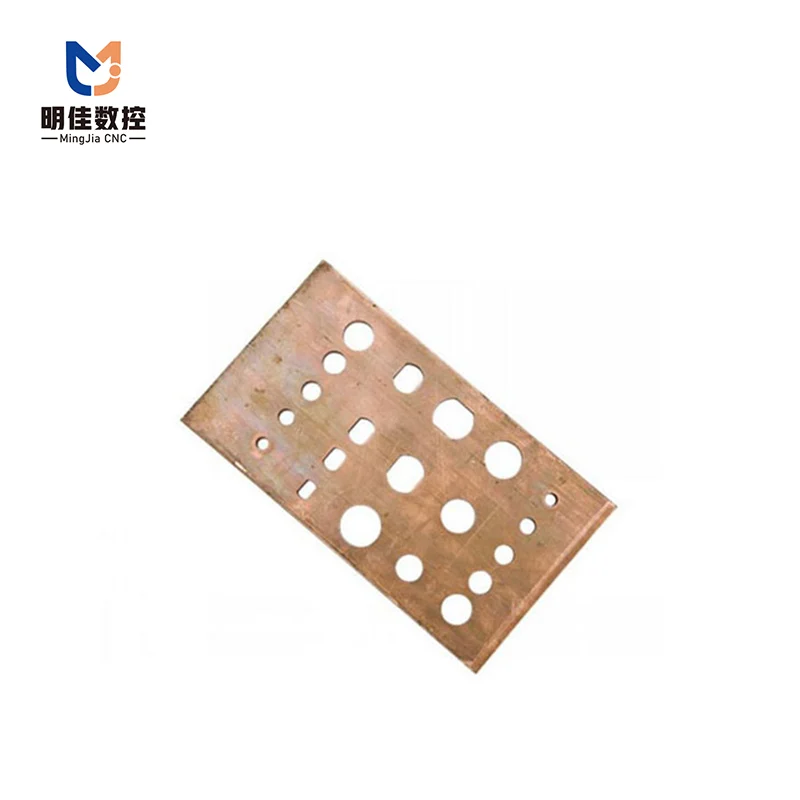

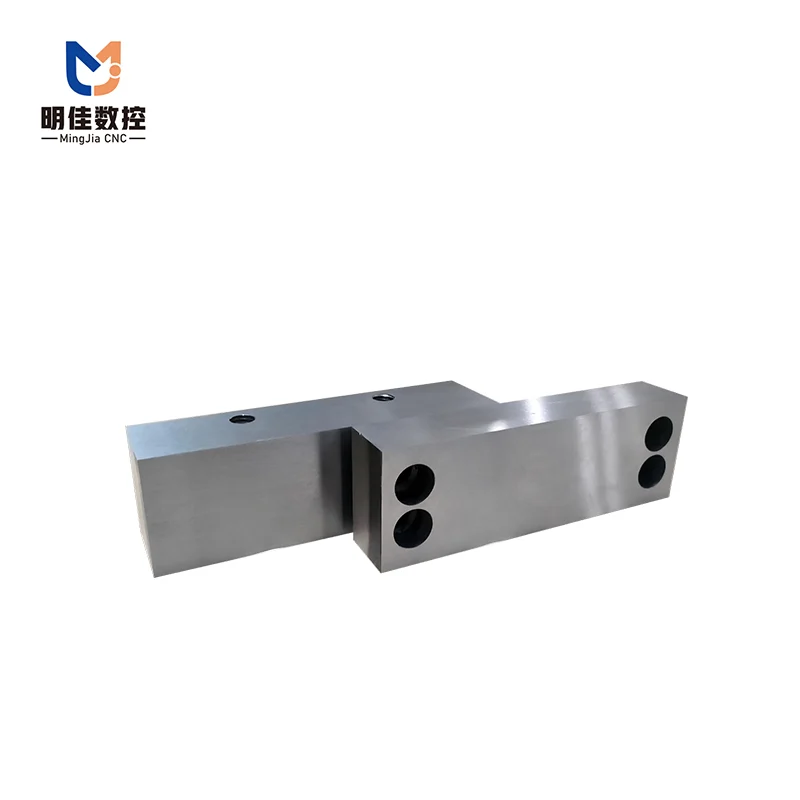

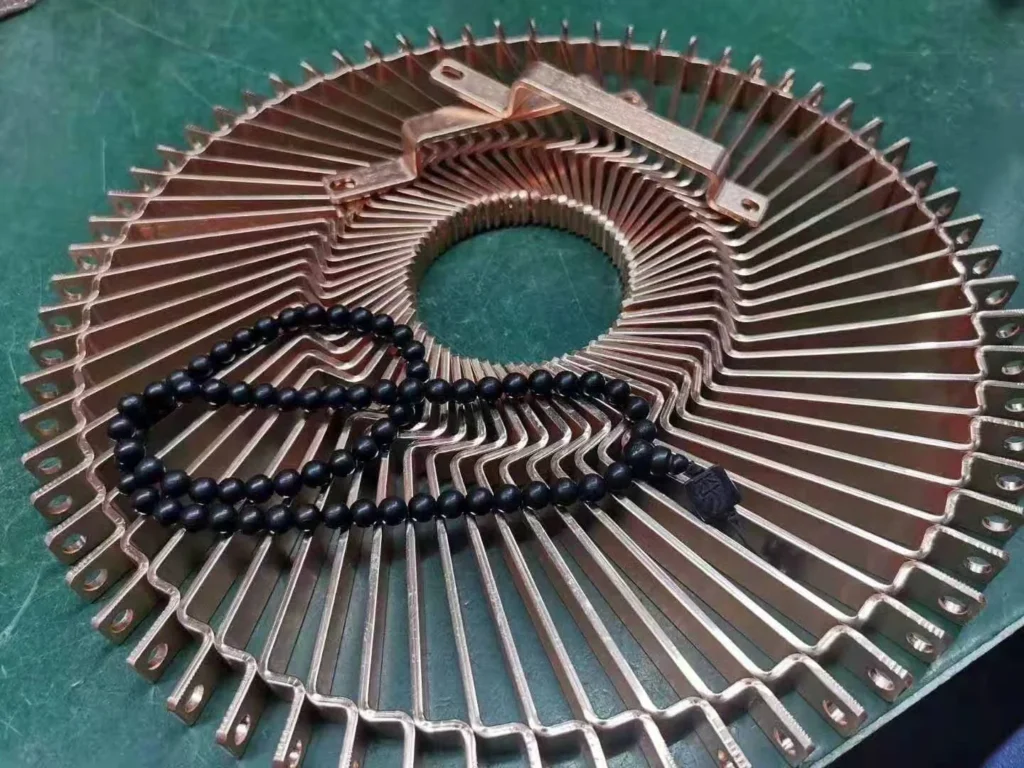

finished product display

main features

1.Guaranteed Precision: How Our Molds Deliver Unwavering Accuracy

Precision is engineered into every mold. Fabricated from premium-grade tool steel, our dies are machined to exceptional tolerances and treated for superior wear resistance. This material and manufacturing commitment directly translates to unmatched dimensional consistency in every punching, shearing, and bending operation, ensuring your busbars meet the most stringent specifications—batch after batch.

2.Durability Through Advanced Metallurgy

Core Process: All critical mold components undergo precision heat treatment.

Key Properties: This process develops a microstructure that delivers high surface hardness combined with excellent toughness and impact resistance.

Operational Benefit: The result is a mold that maintains its integrity over an extended service life, providing reliable performance and reducing the total cost of ownership through fewer changeovers.

3.Optimized Design for Maximum Productivity

The high processing efficiency is a direct result of purpose-driven mold design. Every aspect, from the guiding mechanisms to the cutting geometry, is optimized to minimize non-productive time. This allows for faster cyclingbetween punching, shearing, and bending operations, leading to a significant increase in overall equipment effectiveness (OEE).

4.Engineered for Safety: Precision That Protects

Safety is integral to our design. The precise positioning and secure locking of the dieseffectively eliminate misalignment during operation. This critical feature prevents processing errors and mitigates operational risks, thereby ensuring enhanced safety for both personnel and equipment throughout the production cycle.

5.One Tooling System, Unlimited Configurations

Adapt to any job with unmatched flexibility. Our modular mold system allows for quick and tool-less replacement of components, enabling seamless switching between different specifications of copper or aluminum busbars. This design eliminates the need for dedicated, single-purpose tooling, dramatically broadening your application range and empowering you to meet diverse customer demands with a single investment.

6.Precision Beyond the Bend: Consistent Angles, Zero Guesswork

Achieve flawless bends, every time. Our optimized bending die geometry is engineered to deliver a wide range of precise angles and complex shapes. This advanced design actively controls material flow and stress distribution, resulting in highly accurate forming with minimal springback. Eliminate rework and ensure perfect fit-up with predictable, repeatable results.

7.Service-Friendly Engineering

Ease of maintenance is a core design principle. The modular and simplified mold construction eliminates unnecessary complexity. Combined with standardized connections and accessible components, this enables quick and convenient installation, disassembly, and reassembly. The result is facilitated daily maintenance and upkeep, lowering the total cost of ownership by minimizing labor hours and technical skill requirements for servicing.

8.From Precision Tooling to Premium Products

Enhanced end-product quality is the direct outcome of our mold’s performance. Stable and repeatable processing minimizes variation and defects—most notably burrs and unwanted deformations. By delivering such consistent forming accuracy, our molds play a critical role in elevating the overall finish, structural integrity, and assembly fit of the busbars, directly contributing to higher customer satisfaction.

FAQ

The equipment is primarily designed for manufacturing copper and aluminum busbars, particularly suitable for standard rectangular busbars. The processing width, thickness, and length can be configured or customized according to the client's specific requirements, ensuring long-term stable operation without overload.

The standard configuration typically includes punching, shearing, and bending stations, enabling continuous multi-step processing. This multi-station design effectively reduces the turnaround time of the busbar between different machines, thereby enhancing overall processing efficiency.

The equipment features a high-rigidity integral structure and a stable hydraulic system, combined with precise positioning technology to ensure consistent hole positions, lengths, and bending angles, making it ideal for batch continuous production.

The system supports customized configurations including tonnage capacity, busbar specifications, power voltage, control modes, mold configurations, and automation levels, ensuring seamless alignment with clients' actual production requirements.

The operational logic is clear, and the control system is user-friendly. Ordinary employees can operate independently after brief training, reducing reliance on highly skilled workers.

The equipment is engineered for industrial continuous operation. With proper operation and maintenance, it maintains stable performance under high-intensity conditions.

Routine maintenance primarily involves basic inspections and periodic upkeep, which are low-complexity. We provide detailed maintenance guidance to help extend the service life of your equipment.

We provide remote technical support, video tutorials, hands-on training, and spare parts assistance, covering basic operations, mold assembly/disassembly, routine maintenance, and troubleshooting (including alarm handling and hydraulic leak resolution) to ensure long-term stable operation of your equipment.

You Might Also Like

Leave Message

*Note: Please be sure to fill in the information accurately, and keep the communication unblocked, we will get in touch with you as soon as possible.