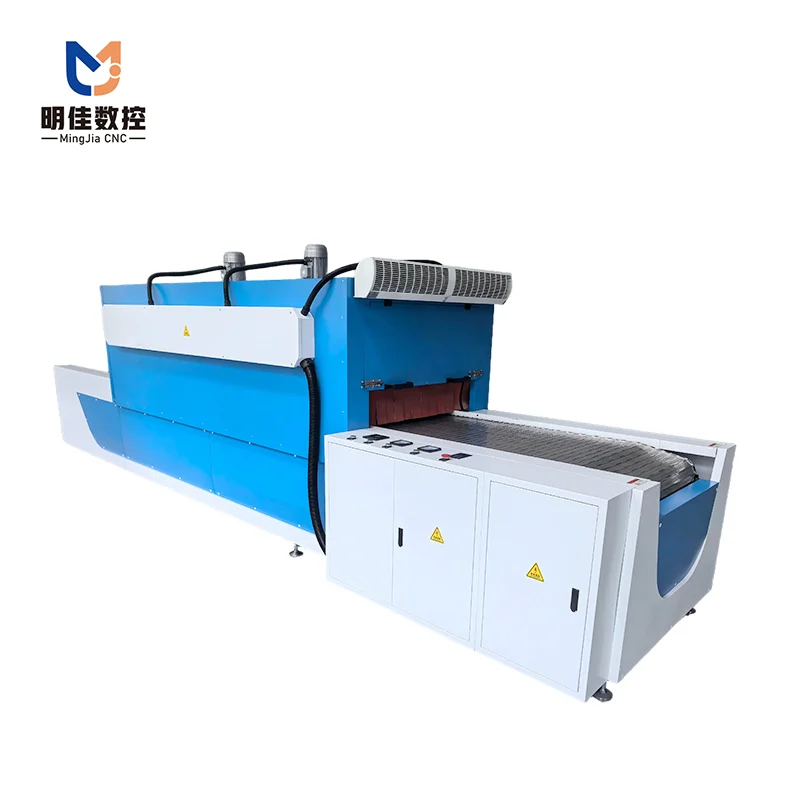

Heat Shrink Tube Forming Machine

Gallery not found. The Busbar Heat Shrinking Machine is primarily designed for heating and shrinking sleeves onto copper and aluminum busbars. The machine consists of a main frame, a conveyor belt system, a heating hood, and an electrical control unit. The conveyor is mounted on the frame, with the heating hood positioned above. The hood houses the […]

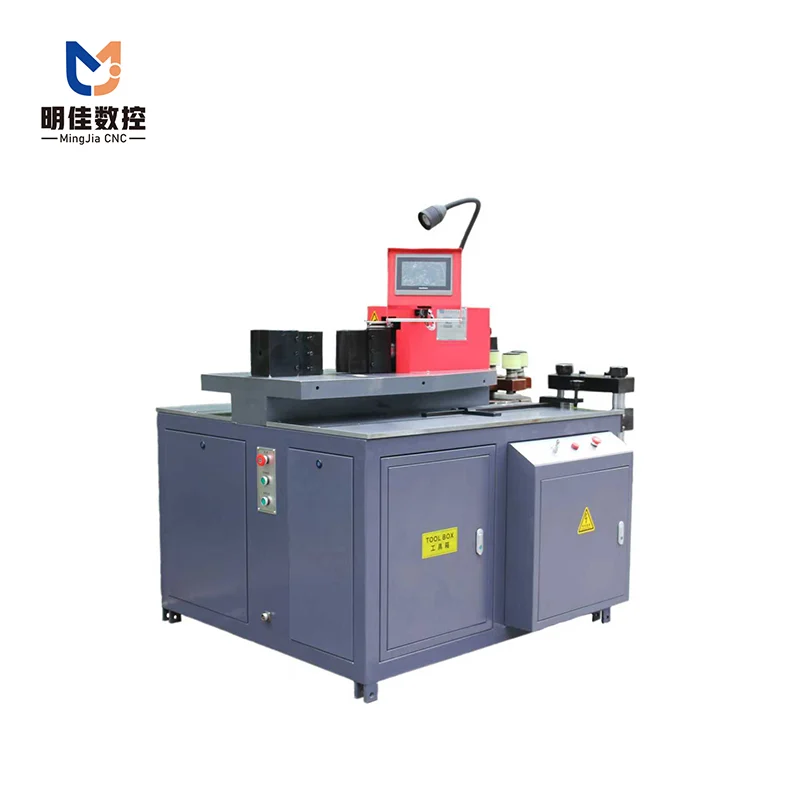

NCXJ-200 CNC Busbar Chamfering Machine

Gallery not found. Facebook Youtube Instagram Get In Touch main features The Precision Arc Profiling Machine: Automated Solutions for Copper Busbar Ends Designed for high-precision, arc-shaped cross-section profiling of copper busbar ends up to 15mm × 200mm, this machine streamlines a complex finishing process into a single, automated cycle. 1、(Adaptive Intelligent Clamping): Utilizes automatic centering technology to locate and secure […]

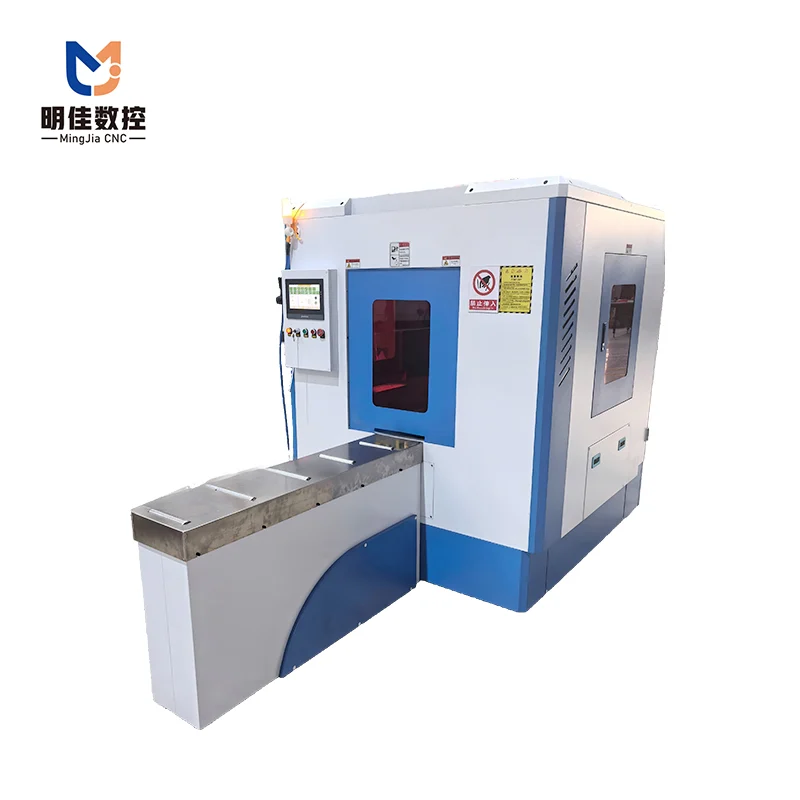

NCZMXB-303-3-S Closed Type CNC Busbar Machine

Gallery not found. Facebook Youtube Instagram Get In Touch main features The Integrated CNC Busbar Processing Center: Precision, Speed, and ReliabilityElevate your busbar production with our all-in-one CNC Processing Center, engineered for unmatched precision and efficiency. Controlled by a robust PLC system, it surpasses traditional relay logic in stability and reliability, ensuring consistent, high-quality output. Intelligent […]

NCZMXK-303-3-S Open Type CNC Busbar Machine

Gallery not found. Facebook Youtube Instagram Get In Touch main features 1.PLC + Servo control for superior stability over relay systems. Performs automatic calculations(angle, Z-bend, length) and compensations. 2.Simultaneous operation of punching, shearing, and bending stations maximizes productivity. 3.Dual-column shear with smooth blade eliminates burrs, waste, and collapse. 4.4/6/8-position integral rotary turret ensures perfect die […]

NCZMXB-303-3-S (Four-axis Servo) CNC Busbar Processing Machine

Gallery not found. NCZMXB-303-3-S (Four-axis Servo) CNC Busbar Processing Machine is equipped with a German Siemens CNC system and servo motors, enabling automatic feeding and positioning for punching, shearing, and bending. It features automatic calculations for bending angles, Z-bends, and material length, along with angle compensation, spring-back compensation pressure holding, and automatic start-stop functions. Four Axis Servo CNC […]

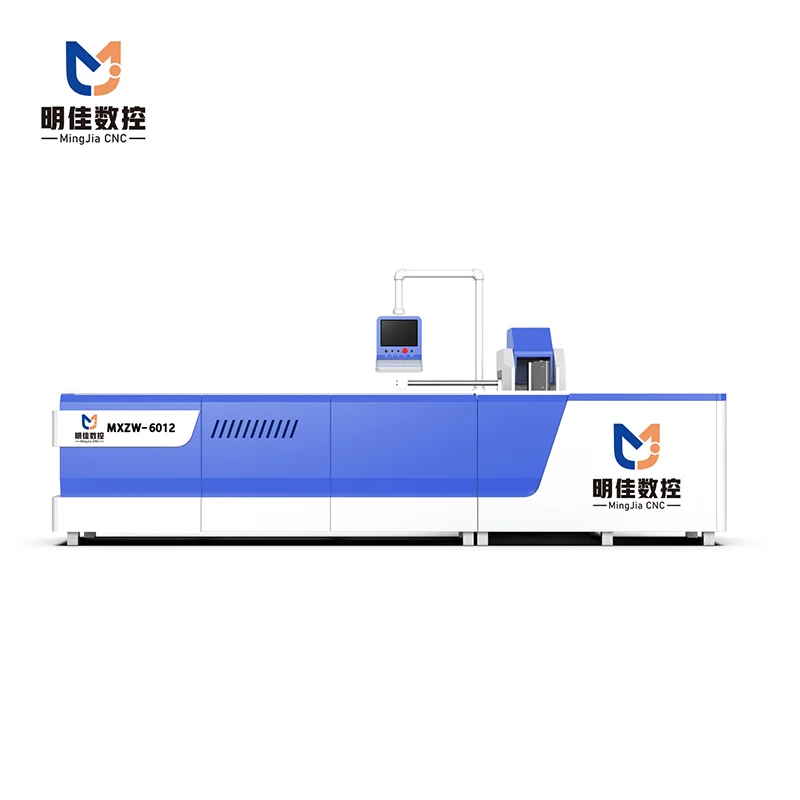

MXZW-6012 CNC Busbar Bending Machine

Gallery not found. Facebook Youtube Instagram Get In Touch main features Intelligent Control System• Simple: User-friendly Siemens touchscreen interface• Reliable: Minimal failure points, easy maintenance• Efficient: High productivity with low energy consumption• Precise: Exceptional accuracy and repeatability Built Strong, Designed Smart.Our closed bending structure starts with an 80mm T10 steel platform for unshakeable strength. The result? A logical, open layout that makes loading […]

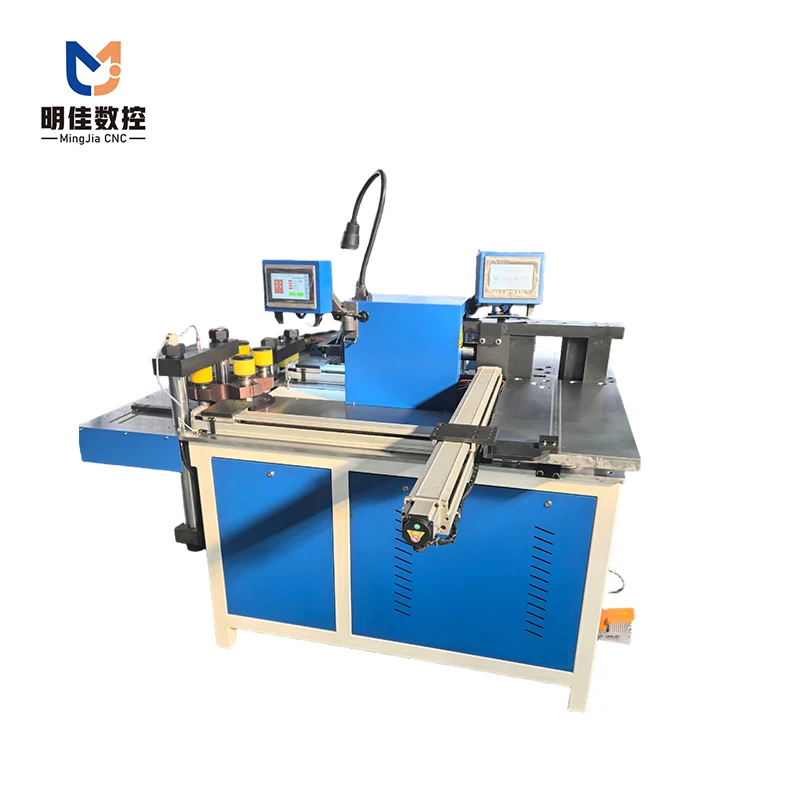

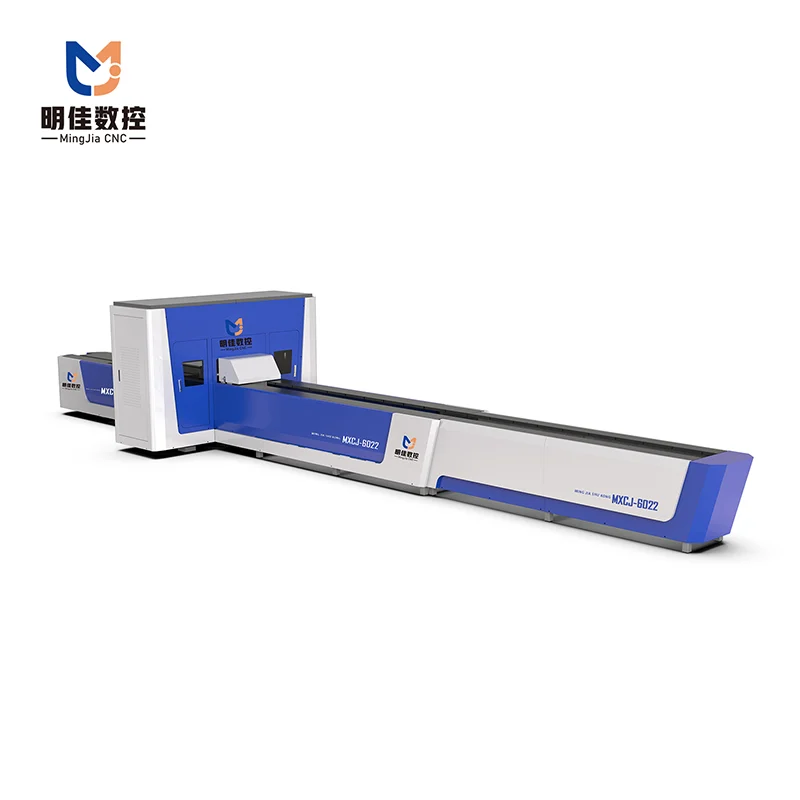

CNC Busbar Punching and Shearing Machine (CNC Busbar Processing Center)

Gallery not found. Facebook Youtube Instagram Get In Touch main features Precision, Powered by Siemens CNC. Our machine features a Siemens CNC operating system at its core, designed for both simplicity and advanced capability. Easy Point & Go Programming: Intuitive coordinate input allows for quick setup with minimal training. Direct CAD Import: Generate machining programs instantly from […]