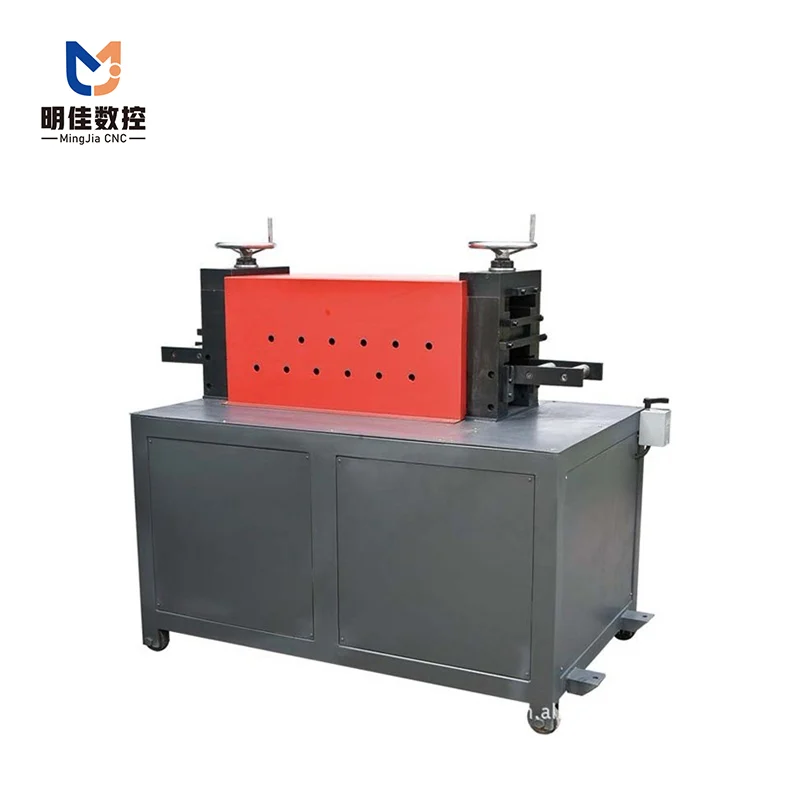

MX JP160/260 Busbar Leveling Machine

This machine is mainly used for straightening/leveling copper and aluminum busbars that have become bent during transportation or processing.

The process ensures no damage to the busbar surface, resulting in a flat, smooth, and aesthetic finish.

main features

13-Roller Busbar Leveling Machine: Fast, Efficient, and Engineered for Longevity

This 13-roller leveling machine is engineered for high-speed, efficient straightening of busbars. It features simple, convenient operation and is designed for seamless integration into busbar processing lines to enhance overall workflow productivity.

1、Curvature Compensation Technology: Unlike traditional roller levelers, our machine incorporates advanced curvature compensation technology. This innovation significantly reduces workpiece skidding, ensures more rational force distribution during the leveling process, and results in a superior finish.

2、Exceptional Energy Efficiency: The optimized force application saves over 50% in power consumption compared to conventional models, dramatically lowering your operational costs.

3、Built to Last: The efficient force distribution and reduced mechanical stress greatly extend the overall service life of the machine, ensuring a better return on your investment.

technical parameter

| Model number | MXJP-160 | MXJP-260 |

| Whole machine dimensions (length * width * height) | 1250 * 800 * 1150 | 1350 * 1000 * 1250 |

| Machine weight | 700kg | 1000kg |

| Motor power | 3kw | 4kw |

| Unevenness | < 1 mm/m | < 1 mm/m |

| Maximum machined width | 160mm | 260mm |

| Maximum machining thickness | 12mm | 16mm |

| Levelling roll line speed speed | 30 m/min | 30 m/min |

| Roller speed | 100 RPM | 100 RPM |

| Calibrate roll diameter | 80mm | 100mm |

| Number of leveling rolls | 13 | 13 |

| Roller processing requirements: heat treatment tempering HB220-250, cylindrical grinding finish 0.8 electroplating hard chrome | ||

FAQ

The equipment is primarily designed for manufacturing copper and aluminum busbars, particularly suitable for standard rectangular busbars. The processing width, thickness, and length can be configured or customized according to the client's specific requirements, ensuring long-term stable operation without overload.

The standard configuration typically includes punching, shearing, and bending stations, enabling continuous multi-step processing. This multi-station design effectively reduces the turnaround time of the busbar between different machines, thereby enhancing overall processing efficiency.

The equipment features a high-rigidity integral structure and a stable hydraulic system, combined with precise positioning technology to ensure consistent hole positions, lengths, and bending angles, making it ideal for batch continuous production.

The system supports customized configurations including tonnage capacity, busbar specifications, power voltage, control modes, mold configurations, and automation levels, ensuring seamless alignment with clients' actual production requirements.

The operational logic is clear, and the control system is user-friendly. Ordinary employees can operate independently after brief training, reducing reliance on highly skilled workers.

The equipment is engineered for industrial continuous operation. With proper operation and maintenance, it maintains stable performance under high-intensity conditions.

Routine maintenance primarily involves basic inspections and periodic upkeep, which are low-complexity. We provide detailed maintenance guidance to help extend the service life of your equipment.

We provide remote technical support, video tutorials, hands-on training, and spare parts assistance, covering basic operations, mold assembly/disassembly, routine maintenance, and troubleshooting (including alarm handling and hydraulic leak resolution) to ensure long-term stable operation of your equipment.

You Might Also Like

Leave Message

*Note: Please be sure to fill in the information accurately, and keep the communication unblocked, we will get in touch with you as soon as possible.