CNC Busbar Punching and Shearing Machine (CNC Busbar Processing Center)

main features

Precision, Powered by Siemens CNC.

Our machine features a Siemens CNC operating system at its core, designed for both simplicity and advanced capability.

Easy Point & Go Programming: Intuitive coordinate input allows for quick setup with minimal training.

Direct CAD Import: Generate machining programs instantly from your CAD drawings, eliminating manual translation errors.

Integrated Simulation Suite: Perform bend calculations, unfolding, and full process simulation within the software to prevent costly errors and ensure first-part correctness.

Streamline From CAD to Reality with Intelligent Software.

Load your 3D/CAD models directly into our intelligent software to automatically generate machining programs, eliminating manual coding and its associated errors. Go beyond basic conversion: the integrated suite performs accurate bending/unfolding calculations and full machining simulations before production starts. The real-time 3D visual display of the workpiece provides an intuitive preview, ensuring flawless setup and first-part correctness.

The modular die library is offered in two optimized configurations:

Linear 7+1/8+1 Setup: A linear arrangement with seven (or eight) stroke positions plus dedicated cutting and embossing stations.

Dual Shear Tooling Options: Choose between double-edged punch-shear tools for standard cuts or single-edged offset-shear tools for specialized applications.

Result: Both deliver exceptionally clean, burr-free cuts with high precision, minimizing secondary finishing.

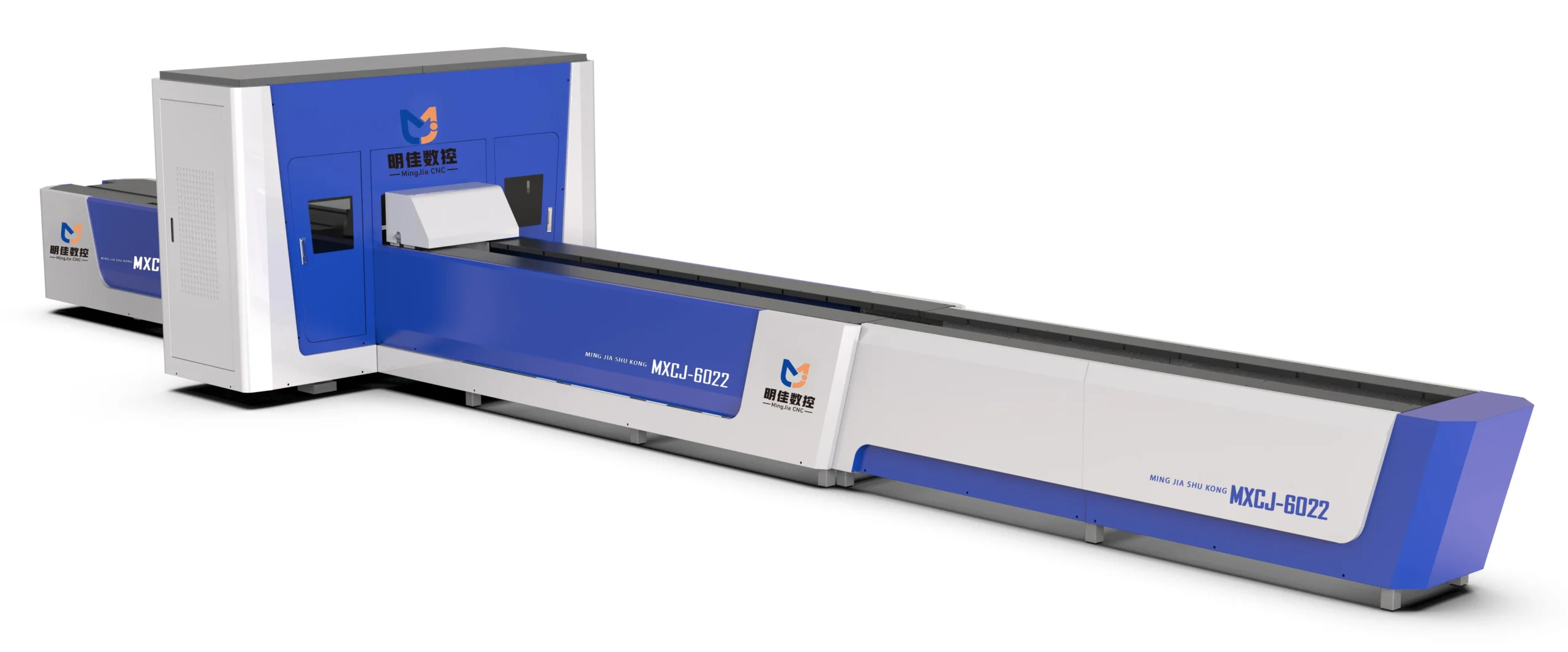

Engineered for Reliable High-Speed Performance.

At the heart of the equipment lies a fully imported, high-precision hydraulic valve block. This premium configuration delivers exceptional pressure control accuracy and rapid response speed. The result is a system engineered for enduring reliability, capable of sustaining a high striking frequency of 120-150 strokes per minute. This ensures the machine meets the rigorous demands of high-intensity, high-efficiency busbar processing without compromise.

The equipment’s hydraulic system incorporates fully imported, high-precision valve assemblies, enabling superior pressure control accuracy and response speed. While ensuring long-term stable operation, it achieves a striking frequency of 120-150 cycles per minute, meeting the requirements for high-intensity, high-efficiency busbar processing.

technical parameter

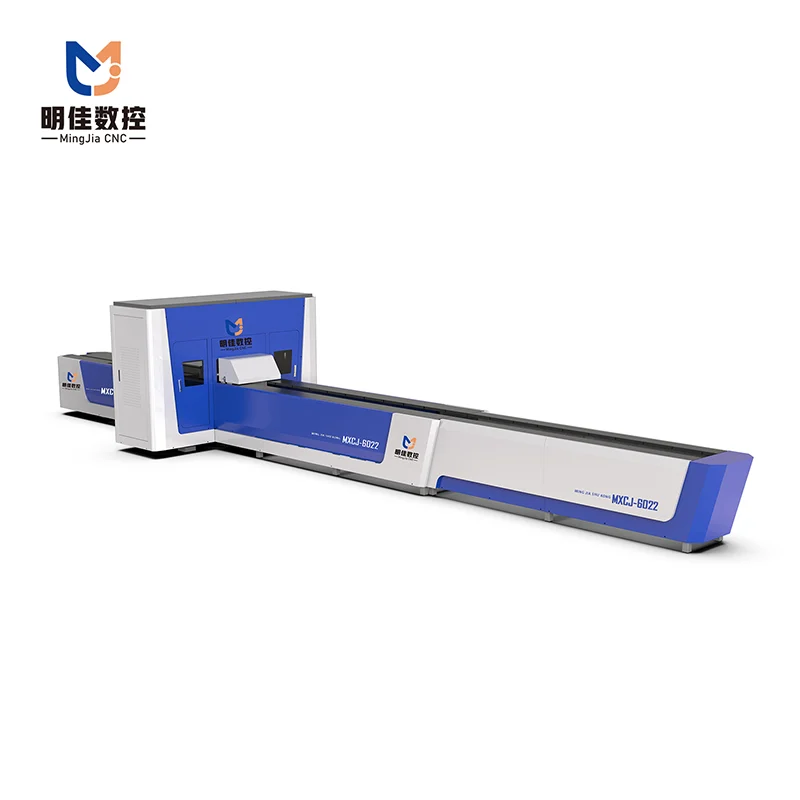

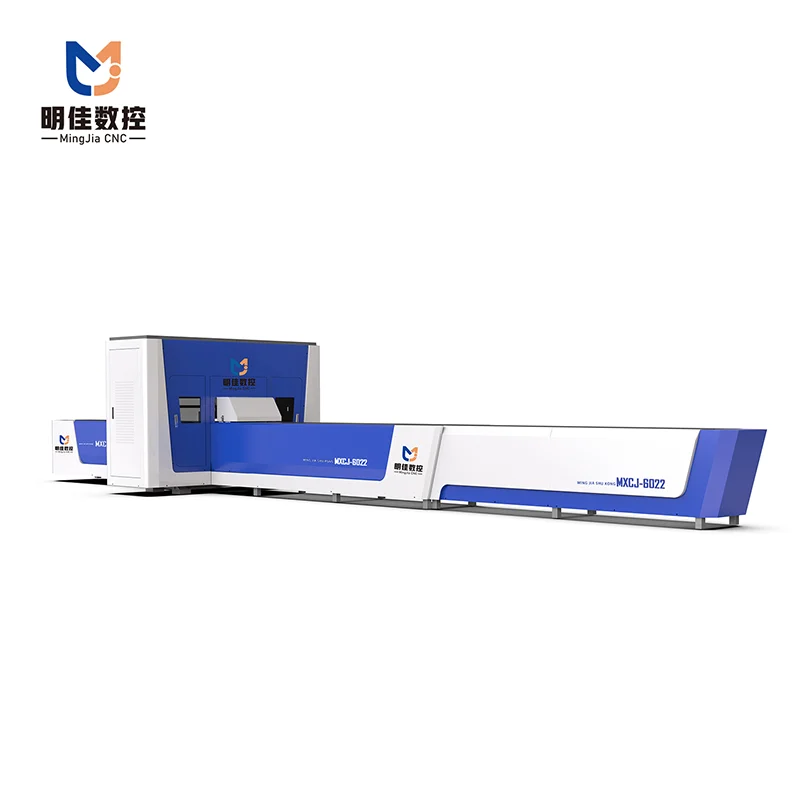

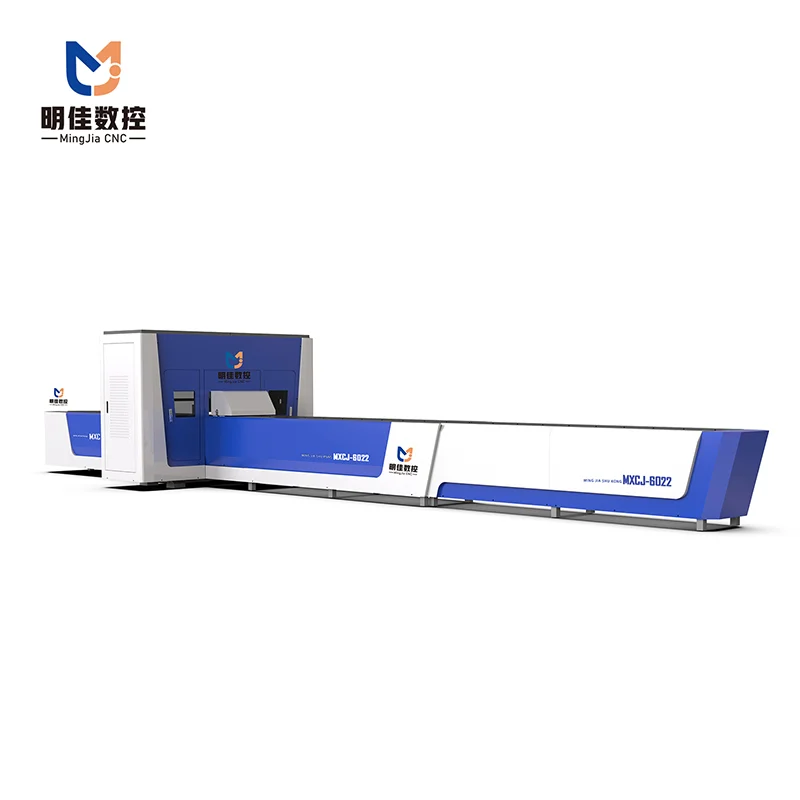

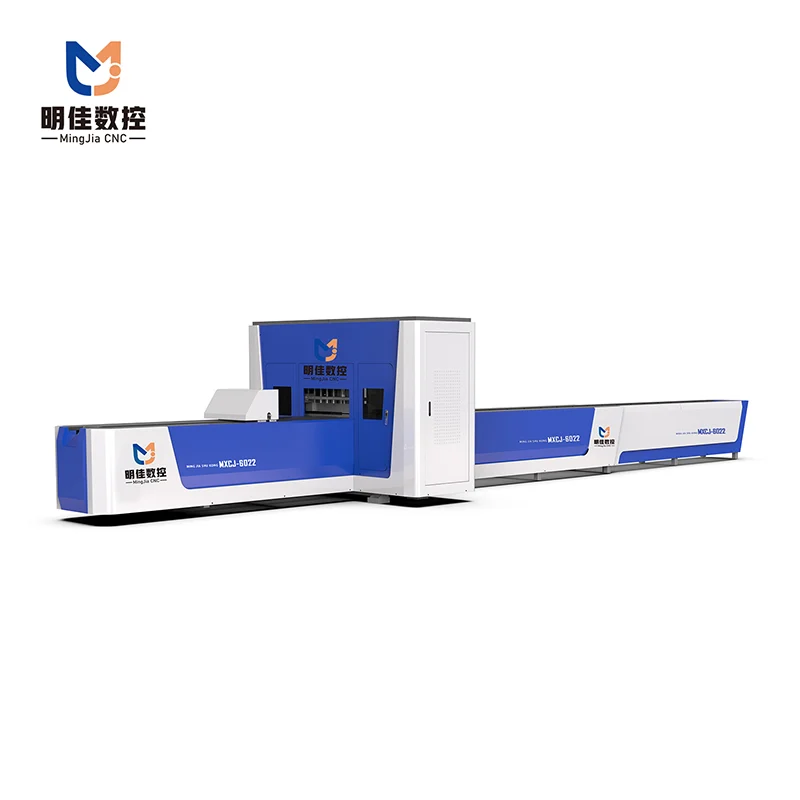

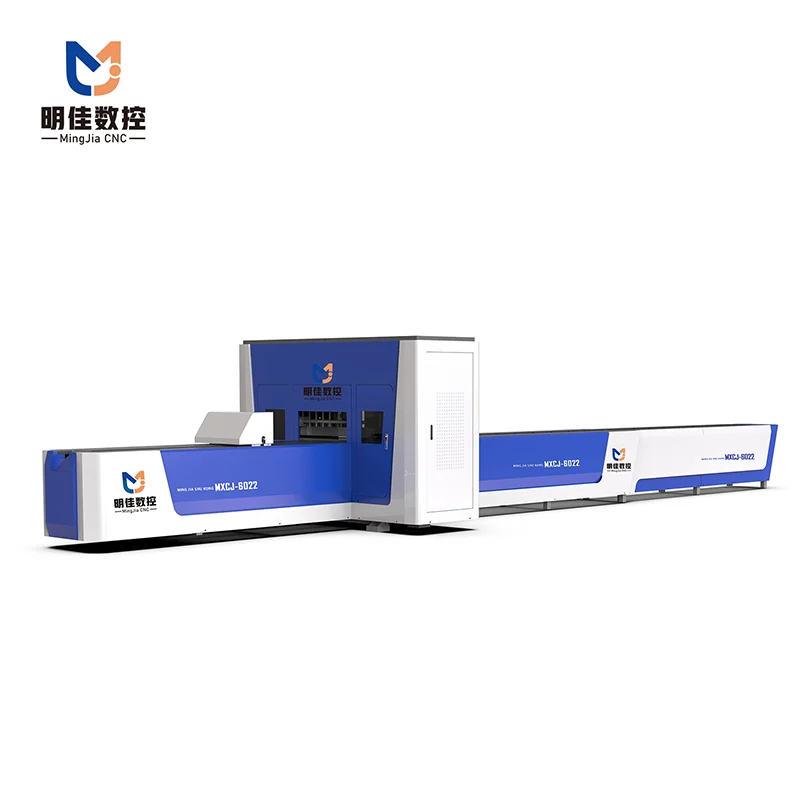

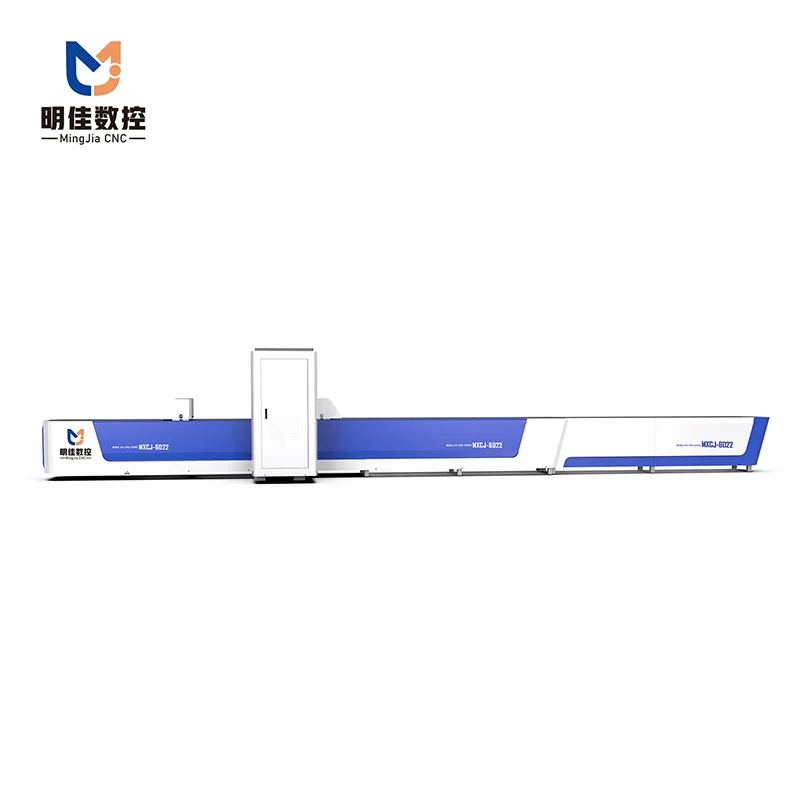

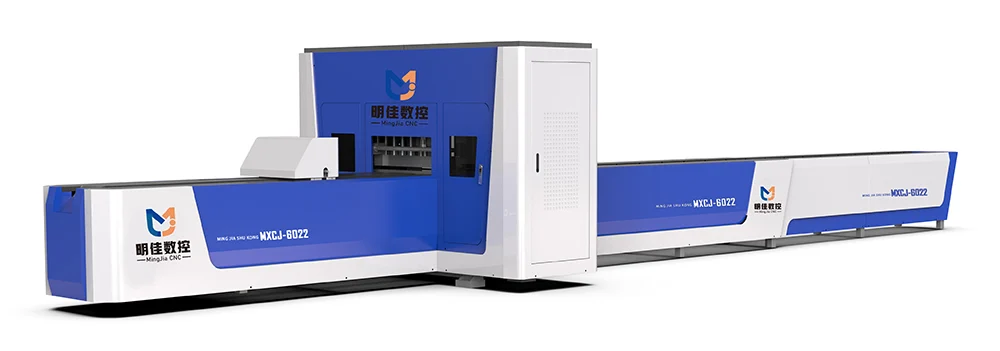

| Model | MXCJ-5022 | MXCJ-6022 | |||

| Nominal pressure | 500KN | 600KN | |||

| Numerical control system | Siemens | ||||

| Strike frequency | 80 times per minute | 120-150 beats per minute | |||

| Control axis count | 3 | 6 | |||

| Maximum X-axis stroke | 1400mm | ||||

| Maximum Y-axis stroke | 500mm | ||||

| Maximum X-axis stroke | 1100mm | ||||

| Mode number | Seven punches, one cut, one embossing; or eight punches, one cut. | ||||

| Machine tool running accuracy | ±0.05mm | ||||

| Aperture distance accuracy | ±0.2mm | ||||

| Punching range | Ø5-Ø32 | ||||

| Shearing range | 200mm*12mm | ||||

| Total weight | 4500KG | 6200KG | |||

| Power of motor | 17kw | 20kw | |||

| External dimensions | 8500mm*3300mm*2000mm | 10500mm*2750mm*2000mm | |||

| Random attachments | Eight sets of punching dies: φ7, φ9, φ11, φ13, φ17, φ21, φ11×15, φ13×17; one set of shearing dies; one set of embossing dies. | ||||

FAQ

The equipment is primarily designed for manufacturing copper and aluminum busbars, particularly suitable for standard rectangular busbars. The processing width, thickness, and length can be configured or customized according to the client's specific requirements, ensuring long-term stable operation without overload.

The standard configuration typically includes punching, shearing, and bending stations, enabling continuous multi-step processing. This multi-station design effectively reduces the turnaround time of the busbar between different machines, thereby enhancing overall processing efficiency.

The equipment features a high-rigidity integral structure and a stable hydraulic system, combined with precise positioning technology to ensure consistent hole positions, lengths, and bending angles, making it ideal for batch continuous production.

The system supports customized configurations including tonnage capacity, busbar specifications, power voltage, control modes, mold configurations, and automation levels, ensuring seamless alignment with clients' actual production requirements.

The operational logic is clear, and the control system is user-friendly. Ordinary employees can operate independently after brief training, reducing reliance on highly skilled workers.

The equipment is engineered for industrial continuous operation. With proper operation and maintenance, it maintains stable performance under high-intensity conditions.

Routine maintenance primarily involves basic inspections and periodic upkeep, which are low-complexity. We provide detailed maintenance guidance to help extend the service life of your equipment.

We provide remote technical support, video tutorials, hands-on training, and spare parts assistance, covering basic operations, mold assembly/disassembly, routine maintenance, and troubleshooting (including alarm handling and hydraulic leak resolution) to ensure long-term stable operation of your equipment.

You Might Also Like

Leave Message

*Note: Please be sure to fill in the information accurately, and keep the communication unblocked, we will get in touch with you as soon as possible.