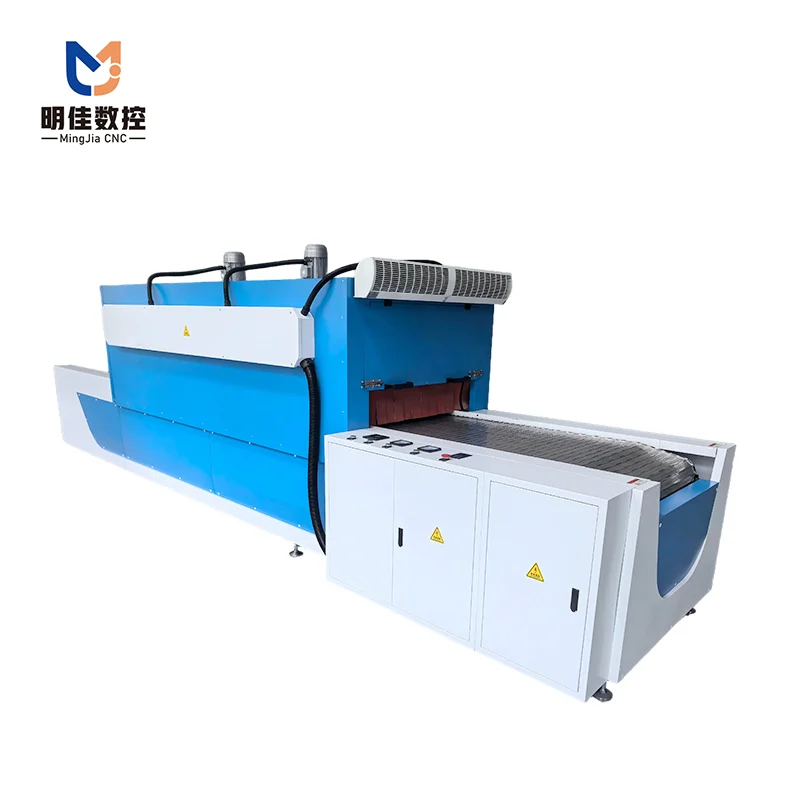

Heat Shrink Tube Forming Machine

The Busbar Heat Shrinking Machine is primarily designed for heating and shrinking sleeves onto copper and aluminum busbars.

The machine consists of a main frame, a conveyor belt system, a heating hood, and an electrical control unit.

The conveyor is mounted on the frame, with the heating hood positioned above. The hood houses the heating elements, temperature sensors, and cooling fans. The integrated electrical control system enables precise regulation of both temperature and speed.

main features

The Intelligent Shrinking System: Perfect Finish, Maximum Efficiency

Achieve flawless, consistent heat-shrink tubing application on busbars with our intelligent system. Engineered for perfection and productivity, it eliminates defects, slashes energy use, and dramatically increases output.

1.Perfect Formation, Zero Defects

An intelligent constant-temperature heating module with optimized duct circulation ensures comprehensive, uniform heat distribution across the entire area, eliminating cold spots.

Guarantees 360° uniform shrinkage, resulting in a smooth, seamless finish on the busbar—free from wrinkles, air bubbles, or localized carbonization from overheating.

This high-precision molding process significantly improves product yield and consistency.

2.High Thermal Efficiency, Lower Costs

A closed insulation chamber coupled with a waste heat recovery system minimizes thermal loss, improving heat utilization efficiency by over 30% compared to traditional open heaters.

The on-demand power adjustment mode avoids idle energy consumption, leading to substantially lower operating costs over time.

3.Unmatched Productivity & Uptime

The continuous feeding conveyor system allows for processing single or multiple busbars simultaneously, cutting the per-unit forming cycle time by half.

Designed for 24/7 continuous, stable operation without frequent shutdowns or adjustments, it increases average daily production capacity by over 80%, maximizing your return on investment.

technical parameter

| Studio dimensions (width x height x length) | 1000x200x3000mm |

| Dimensions (width x height x length) | 1400x1450x6000mm |

| Equipment Area | The feeding zone measures 1500mm in length, the baking zone 3000mm, and the discharge zone 1500mm. |

| Temperature range | RT+250℃ |

| Heating rate | RT+250℃ ≤30min |

| Lavin accuracy | ≤±1℃ |

| Temperature uniformity | ≤±5℃(Note: The above performance indicators are measured values obtained at room temperature of +25℃ in the absence of samples.) |

| Inner box material | Stainless steel, thickness 1.2mm |

| Outer box material | Cold plate thickness 1.5mm |

| Insulation Material | Ceramic Fiber Insulation Cotton |

| Conveyor Belt | Stainless steel conveyor belt with 38mm chain and stainless steel mesh belt. |

| Adjustable conveying speed | (0.5-2 m/min) via frequency conversion |

| Drive of conveyer | 0.37kw horizontal speed reducer motor |

| Inlet/Outlet Baffle | Adjustable baffle with 0-200mm range |

| Thermal insulation layer thickness | ≥120mm |

| Heater | Stainless steel heating element, heating power 36 kW |

FAQ

The equipment is primarily designed for manufacturing copper and aluminum busbars, particularly suitable for standard rectangular busbars. The processing width, thickness, and length can be configured or customized according to the client's specific requirements, ensuring long-term stable operation without overload.

The standard configuration typically includes punching, shearing, and bending stations, enabling continuous multi-step processing. This multi-station design effectively reduces the turnaround time of the busbar between different machines, thereby enhancing overall processing efficiency.

The equipment features a high-rigidity integral structure and a stable hydraulic system, combined with precise positioning technology to ensure consistent hole positions, lengths, and bending angles, making it ideal for batch continuous production.

The system supports customized configurations including tonnage capacity, busbar specifications, power voltage, control modes, mold configurations, and automation levels, ensuring seamless alignment with clients' actual production requirements.

The operational logic is clear, and the control system is user-friendly. Ordinary employees can operate independently after brief training, reducing reliance on highly skilled workers.

The equipment is engineered for industrial continuous operation. With proper operation and maintenance, it maintains stable performance under high-intensity conditions.

Routine maintenance primarily involves basic inspections and periodic upkeep, which are low-complexity. We provide detailed maintenance guidance to help extend the service life of your equipment.

We provide remote technical support, video tutorials, hands-on training, and spare parts assistance, covering basic operations, mold assembly/disassembly, routine maintenance, and troubleshooting (including alarm handling and hydraulic leak resolution) to ensure long-term stable operation of your equipment.

You Might Also Like

Leave Message

*Note: Please be sure to fill in the information accurately, and keep the communication unblocked, we will get in touch with you as soon as possible.